|

|

- |

|

|

|

|

-

Start Project No. 1 (Chapter

step by step exercises).

-

| To

do this week:

Design

Assignments include:

-

Assignments

1.1a, 1.1i, 1.2a, 1.2f

Four drawings

total. |

These assignments are due

on Friday April 2, on your new drawing template that we will create Thursday

during class. Print out on "A" sized paper (8.5" x 11"), landscape

orientation.

|

- |

|

|

|

|

-

Start the Project No. 1

models (Chapter step by step exercises).

-

| Due

this week:

Design

Assignments include:

-

Assignments

1.12, 1.14, send these via eDrawings as both a drawing and a part, allow

measurements.

Project

Assignments include:

Plate,

Rod and Guide, print out the Plate and Rod and leave in box.

|

Tuesday's class will start

with criteria on grading. Bring your questions.

We will then proceed to

updating our template files. Updates to these files include:

Drawing (see example below)

-

Reduce the "Drawing No." font

so that the drawing name will fit in the space allocated for it

-

Add information for "Drawn By"

(initials) and "Drawn Date" ("Short Date") in the title block

-

Select the "Third Angle" projection

(as opposed to the "First Angle" default) for drawing views

-

Add View Titles to each of the

views.

-

Change the "Bent Leader" length.

Part

-

Insert "Company Name" and "Description"

information in the model properties off of the Pull Down Menu (File, Properties,

Custom Tab).

Start the Project models (Plate,

Rod and Guide) as a series of step by step exercises in the book.

Print out drawings for the Plate and Rod only using your "A sized" drawing

template. We will save the Guide for the Project No. 3 drawing.

Leave these drawings in the box in the lab.

Do Design Assignments 1.12

and 1.14, save as an eDrawing part and drawing, "allow measuring" and send

via email by Friday at 5pm.

|

- |

|

|

|

|

-

| Due

this week:

Design

Assignments due Friday by 5pm include:

-

3.7 on a

B sized drawing template (one drawing).

|

I will not be here for class

on Tuesday, out sick. Please work on Project's #2 and #3. Use

your class time effectively. Stay and seek or give help to others.

Skip the section on Cosmos Express (pages 2-78 - 2-92).

Also on Thursday I will demonstrate

the assembly of the parts for the Guide Rod assembly if needed and start

Project #3.

|

- |

|

|

|

|

-

| Due

this week:

Project

Assignment:

In

class evaluation on Design Assignment 2.3 at the beginning of class on

Tuesday.

In class

evaluation on the Motion Study for your gear design at the beginning of

class on Thursday.

Design

Assignments due Friday by 5pm include:

-

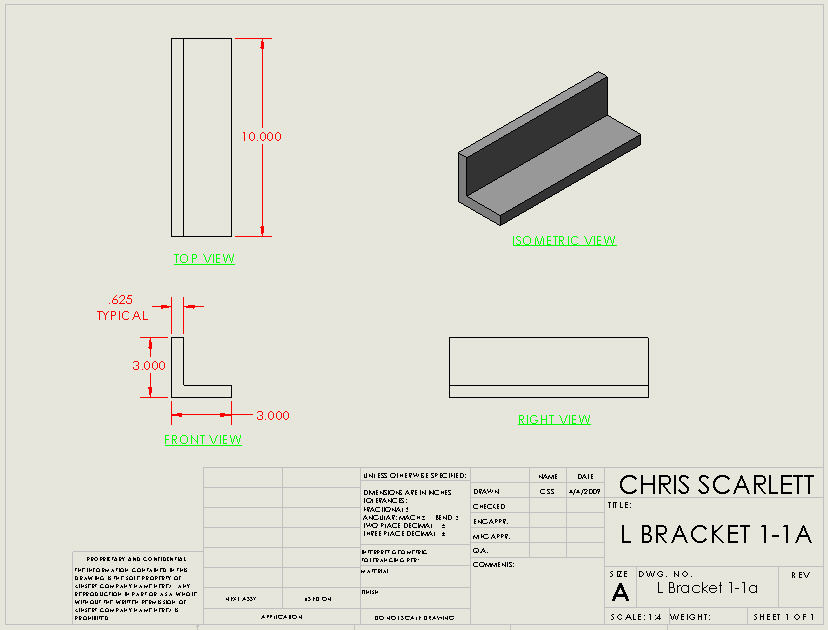

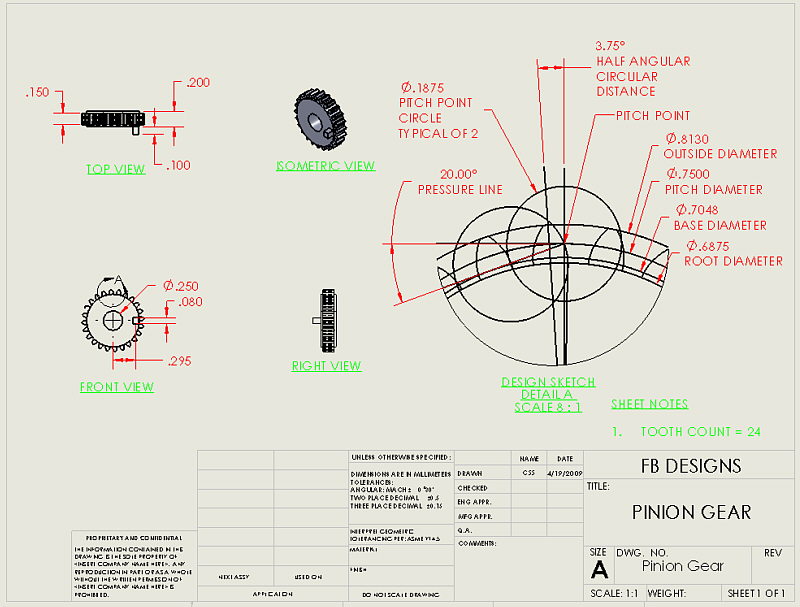

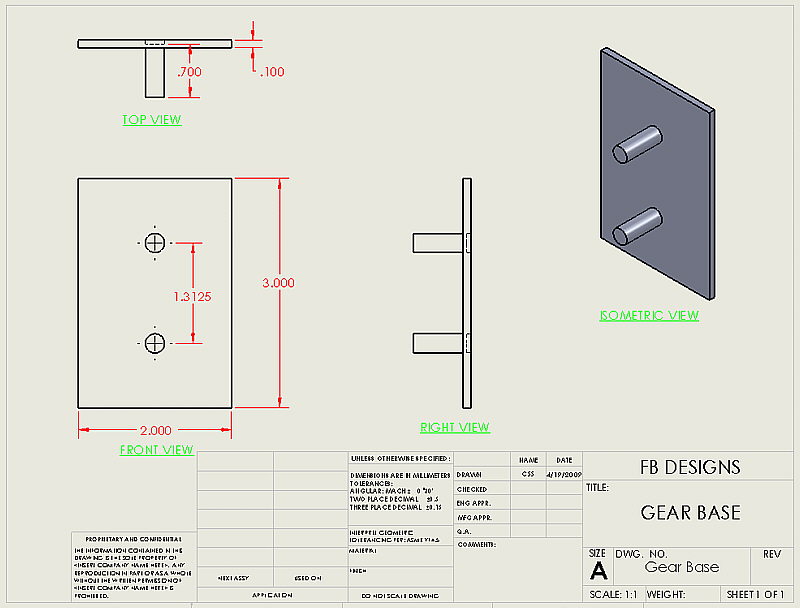

Gear design,

2 gears and mounting plate as parts on your A sized inch drawing

template.

-

Project

#3 Drawing as described in the book. Do not hand in anything on the

sections for the Exploded Views or Bill of Materials. Cover these

sections while reading and modeling and plan on handing these in at a later

date

|

On Tuesday, an in class evaluation

will be conducted for the Design Assignment 2.3. For this evaluation,

I will be looking for proper assembly techniques with points taken off

for incomplete or missing mating references (as described in the book),

missing parts and mating errors. To get a good grade, build all of

the parts properly (check previous week's markups) and follow the book

covering every step described.

Tuesday's class will follow

up with a demonstration on spur gear design. Refer to the Student

Resources link for instructions on this assignment. Also check the

Gradesheet and click on the tab at the bottom left of your window that

states "Gears" for your design parameters. Every student will have

a different Design Assignment. The values that you will need to get

started include the Gear Ratio, Dimetral Pitch and the number of teeth

on the Pinion Gear. The gears and mounting plate will be modeled

and handed in on Friday as Design Assignment drawings, 3 total (see below).

On Thursday, an in class evaluation on a motion study of these gears will

be conducted similar to Tuesday's evaluation. Check out the link

at "Page of helpful class related links" from the "Student Resources Link"

above for more general information on spur gear design.

|

- |

|

|

|

|

-

| Important

this week:

Test

on Tuesday, pre evaluation modeling instructions follow below. The

examination portion is closed book, the modeling portion is open book.

Grading

criteria changes for recent assignments follow below.

Design

Assignments due Friday by 5pm include:

-

4.4 and

4.8 as an eDrawing drawing via email.

YASWUG meeting

on Thursday, Oxford Suites, see information at the top of the website. |

Changes to grading criteria

on recent assignments:

-

Project 3

-

For those that missed the first

week deadline you can hand in this Design Assignment by Friday May 1 for

up to 90% of the original potential grade (up to 18 points in lieu of 70%

or 14 points). No redos for this second deadline.

-

For those that handed in this

assignment but would like to improve your grade you can make the corrections

noted on the markup and hand it back in for up to 100% of the original

potential grade.

-

For those that handed in this

assignment and received a good grade (16 points or better) will get an

automatic 20% (or 4 points) added to your grade without any additional

work.

-

In Class Evaluation for Design

Assignment 2.3. Re-evaluation on Tuesday May 5th.

-

For those that missed this evaluation

last Tuesday you can demonstrate this to me for up to 80% (or 16 points)

of the original potential grade.

-

For those that were present

for the original evaluation you will get 10% (2 points) added to your grade.

-

In Class Evaluation for the

Gear Motion Study. Re-evaluation on Tuesday May 5th.

-

For those that missed this evaluation

last Thursday you can demonstrate this to me for up to 80% (or 16 points)

of the original potential grade.

-

For those that were present

for the original evaluation but did not have it done correctly you can

demonstrate this to me for up to 90% (or 18 points) of the original potential

grade.

-

For those that were present

for the original evaluation and got a full grade (16 points or more) you

will get 20% (4 points) added to your grade.

Test on Tuesday, details

for the pre-evaluation model follow below.

The model portion of the

test will be a garden cart. Yes, a glamorous, sporty, to be envied

by all type of Garden Cart. Units in inches to 3 digits after the

decimal. All parts are plain carbon steel. Prior to the test

you should build the following parts and assembly (or you will not have

enough time on Tuesday):

Cart Side and Floor.

Sketch the following on

the Front Plane before extruding it 43.731 inches. The side is 30

inches at its maximum minus the top lips and the height is 12 inches at

its maximum:

More notes on the above sketch:

The Origin is on the exterior line, the fillet radius on the bottom corners

are measured from the outside, the fillet radius on the upper lip is on

the inside, the upper lip is 1.50" from the inside of the cart to the end

(use the offset sketch entity). Use plain carbon steel for material

and find the thickness of 10 gauge sheet steel for the thickness.

The result should similar to the image below:

More notes on the above sketch:

The Origin is on the exterior line, the fillet radius on the bottom corners

are measured from the outside, the fillet radius on the upper lip is on

the inside, the upper lip is 1.50" from the inside of the cart to the end

(use the offset sketch entity). Use plain carbon steel for material

and find the thickness of 10 gauge sheet steel for the thickness.

The result should similar to the image below:

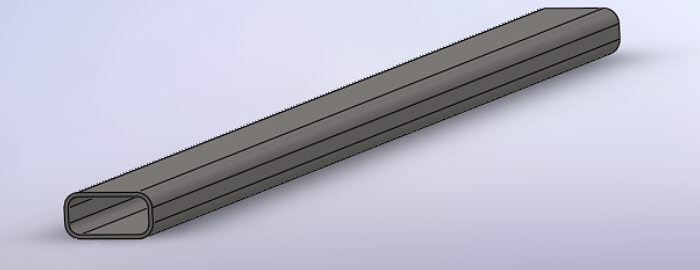

Cart Floor Support, Side.

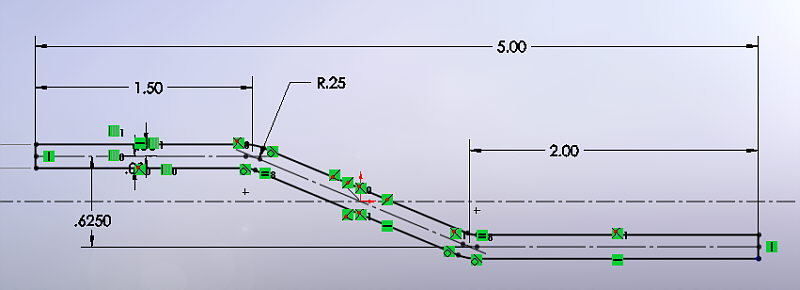

Sketch the following on

the Front Plane before extruding it 44 inches.

More notes on the above sketch:

Start with a Center Rectangle with the above dimensions, fillet the edges

as shown, extrude. The result should similar to the image below:

More notes on the above sketch:

Start with a Center Rectangle with the above dimensions, fillet the edges

as shown, extrude. The result should similar to the image below:

Cart Floor Support, Center.

The sketch for the floor

support in the center is similar to the above but 64 inches long.

There is a hole cut in the front for the Hitch (centered with the Right

Plane).

Cart Hitch Mount.

Sketch the following on

the Right Plane. Start with a construction line with the dimensions

and fillets as shown. Offset this line 1/2 the distance of 8 gauge

sheet steel (look this up) on both sides. Extrude it 2 inches.

Place 2 3/4 inch feature fillets on it and a hole in a position similar

to the one sketched for the floor support.

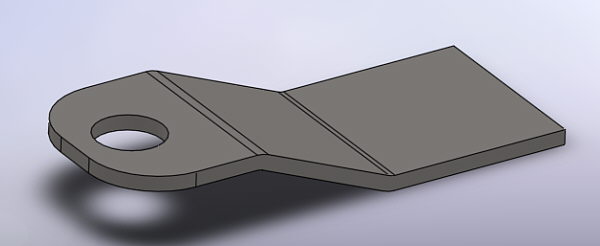

The result should look similar

to the image below:

The result should look similar

to the image below:

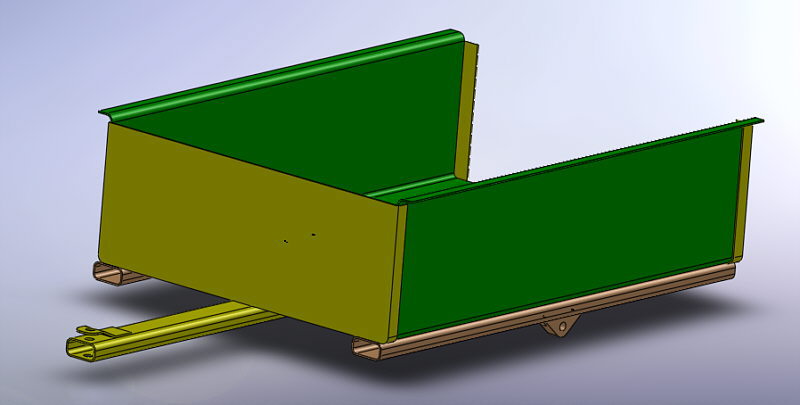

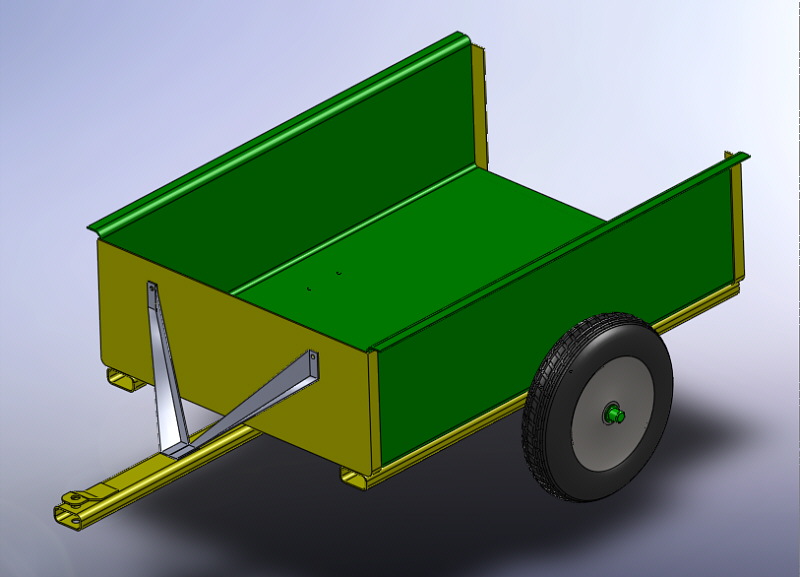

Cart Assembly:

The Cart Assembly (so far)

will look similar to the image below. Part colors are required and

of your choice. The front and rear panels of the cart will be constructed

in class as a class exercise. The wheel mount will be built on your

own during the evaluation. Extra credit is offered for items or features

added that reduce sharp edges on the top lip of the Cart Side and Floor

piece.

This portion of the test will

require a drawing of the Wheel Mount and an in class evaluation of your

assembly.

This portion of the test will

require a drawing of the Wheel Mount and an in class evaluation of your

assembly.

|

- |

|

|

|

|

-

| Due

this week:

Re-evaluations

for the two In Class Evaluations for the Gear motion Study and the Assembly

from Design Assignment 2.3 according to the criteria listed in the Week

5 section above.

Design

Assignments due Friday by 5pm include:

-

4.9 as an

eDrawing drawing via email.

-

Project

#4 as a printed "B" sized drawing on two sheets. The Battery and

Battery Plate on one sheet and the Lens and Bulb on the second sheet.

Skip the part on Mold Tools.

Extra Credit

Assignments due Friday by 5pm may include:

-

PhotoWorks

rendering of all or any combination of the following: cup, challis, vase

and tray using revolved features. Send via email as an eDrawing drawing

and jpg image.

|

Tuesday, we will:

-

Briefly cover the recent examination

and go over the items that will be on the next examination.

-

Re evaluate the two In Class

Evaluations for the Gear Motion Study and the assembly from Design Assignment

2.3 according to the criteria listed in the Week 5 section above.

-

If time permits start Project

4 and extra credit assignments.

-

The extra credit includes rendering

an image in PhotoWorks of your design of all or any combination of the

following: a cup, challis, vase and or a tray or similar objects using

Revolve Features as described in this project. Four maximum.

You will send to me an "A" sized eDrawing drawing with dimensions and a

rendering of the item in PhotoWorks as a JPG file. Save the JPG file

with the highest resolution for more credit (don't send a postage stamp

sized image). The more creativity and effort the more points.

Thursday, we will:

|

- |

|

|

|

|

-

| Due

this week:

Design

Assignments due Friday by 5pm include:

-

4.6 and

4.7 as a printed drawing in the box. Apply GD&T as described

in class on Tuesday.

-

Design a

Pin with tolerancing on it to fit both Design Assignments.

-

3 drawing

total.

Final Project

Abstract due, one page. Refer to the Student Resources link above

for additional information. |

Tuesday

-

We will briefly cover the Final

Project and abstract due at the end of the week. Additional information

can be found at the Student Resources link above.

-

We will cover a lecture on Geometric

Dimensioning and Tolerancing (GD&T). This is the application

of symbology and text to describe tolerances on features other than just

length that we have been using up to now. For example, these tolerances

may be: perpendicularity of a pin to fit in a slot, parallelism of the

sides of the pin along its length, location tolerance of the axis of the

pin and so forth. The slot will have similar tolerances to ensure

that the item with the slot at its Least Material Condition (LMC) will

accommodate the Pin at its Most Material Condition (MMC). Additional

information, via a section in a text book, can be found at the Student

Resources link above.

-

If there is any time we will

work on the Design Assignments or Project No. 5.

Thursday

-

Hand in your drawings per the

following instructions:

-

By Friday at 5pm.

-

Printed on A sized inch template

-

In the box

-

Units in inches to a precision

of 0.123

-

4.6

-

Make the front virtual plane

datum surface A

-

Make the top virtual plane datum

surface B

-

Make the right virtual plane

datum surface C

-

Apply a bilateral tolerance

on the circle that defines the cylindrical cut for the 1" hole to be between

1.000" and 1.003"

-

Make the position of the cylindrical

cut of the 1" hole to have a geometric tolerance of 0.002" referencing

Datum B and Datum C at the most material condition.

-

Make the position of the cylindrical

cut of the 1" hole to have a geometric tolerance of 0.002" that is perpendicular

to Datum A regardless of feature size.

-

Make the back surface of the

block to have a flatness tolerance of 0.001" to Datum A regardless of feature

size.

-

4.7

-

Make the top virtual plane datum

surface A

-

Make the front virtual plane

datum surface B

-

Make the right virtual plane

datum surface C

-

Apply a tolerance on the circle

that defines the cylindrical cut for the 1" hole to be between 1.000" and

1.003"

-

Make the position of the axis

for the cylindrical cut of the 1" hole to have a geometric tolerance that

is parallel to Datum A and Datum C at the most material condition with

a tolerance of 0.002".

-

Make the inside surface of the

back tab, as seen in the top view, parallel to Datum B with a tolerance

of 0.002" at the most material condition.

-

Pin

-

Make the surface on the bottom

of the head of the Pin Datum A

-

Make the cylindrical circular

extrusion of the pin from the head circular with a tolerance of 0.02"

-

Apply a tolerance on the circle

that defines the cylindrical extrusion of the 1" Pin to be between 0.998"

and 0.992"

-

Make the cylindrical circular

extrusion of the pin from the head perpendicular to Datum A with a tolerance

of 0.003" at the most material condition.

|

- |

|

|

|

|

-

| Due

this week:

Design

Assignments due Friday by 5pm include:

-

Project

#3, Exploded View and Bill of Materials (BOM)

-

Exploded

view, 2 views on B sized paper, exploded with paths and collapsed assembly.

-

For the

BOM, exploded assembly with paths, balloons and BOM on B sized paper.

-

-

Project

#5, place your parts on B sized drawings in a similar manner as Project

#4. In class evaluation on Thursday for the Flashlight Assembly.

Final Project

Abstract revisions if any. |

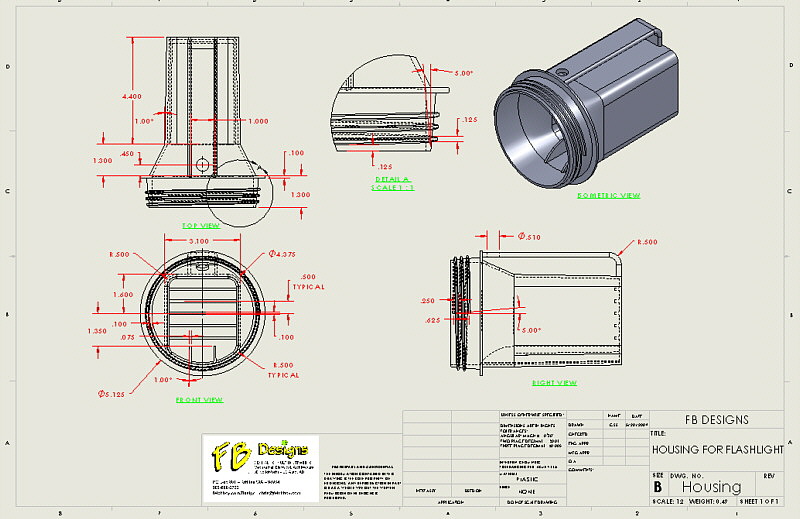

Project #5 Drawings, ignore

the section in Project #5 on eDrawings.

Flashlight Part Drawings,

include the O-Ring, Switch and Lens Cap

-

Parts on B sized paper printed

in the lab

-

Units in Inches, precision to

3 decimals

-

Hidden Lines Visible in the

appropriate views

-

The drawing may look similar

to

the following image, create additional views and add additional dimensional

text if it enhances the information.

Flashlight Housing Drawing,

include the Flashlight only

-

Parts on B sized paper printed

in the lab

-

Units in Inches, precision to

3 decimals

-

Provide a detail of the threads

from the Top View

-

Hidden Lines Visible in the

appropriate views

-

The drawing may look similar

to the following image, create additional views and add additional dimensional

text if it enhances the information.

|

- |

|

|

|

|

-

The model portion of the

examination to be evaluated on Tuesday follow below.

From the first examination

you should have the following parts and an assembly as listed below:

Cart Side and Floor

Cart Floor Support, Side

Cart Floor Support, Center

Cart Hitch Mount

Wheel Mount

Cart Assembly

Before getting started on

the new parts listed below fix any problems that you may have had with

the parts and/or assembly from the last examination.

For this examination you

will build the following parts:

Wheel

Tire

Wheel Tire Assembly

Cart Axle

Cart Wheel Spacer

Cart Axle Hub Cap

Cart Front Support

Wheel

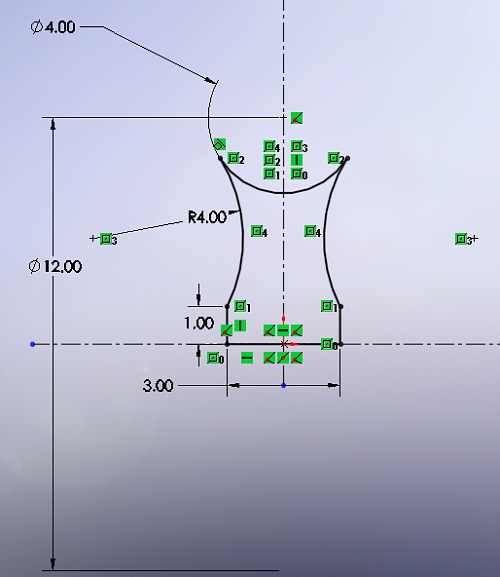

Sketch on the front plane

the sketch below. Use the Revolve Boss/Base feature. Material

is stainless, AISI 304. Hint, draw the two centerlines as shown.

Sketch the circle on the top representing the seat for the tire.

Sketch the bottom line on the axis then the side for the hub, then a 3

point arc from the top of the side for the hub with the other end tangent

to the tire seat circle. Mirror the items on one side to the other,

trim out the top portion of the tire seat circle. Using the horizontal

centerline revolve the sketch. When done with the revolve feature

cut a 0.75" hole in the center for the axle.

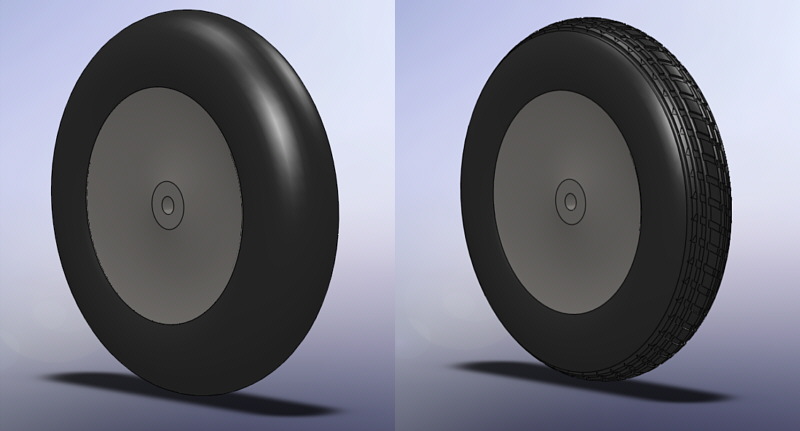

Tire

Sketch on the front plane

the sketch below. Use the Revolve Boss/Base feature.

Material is Rubber. Extra credit for tire treads (sketch cuts in

the sketch shown below and/or sketch a pattern on a plane, use the Offset

from Surface option for an Extrude Cut then apply a Circular Pattern).

Wheel Tire Assembly

Insert both the Wheel and

Tire to the Origin in the assembly.

Cart Axle

Sketch on the right plane,

an axle 0.75" in diameter and 40 inches long (Mid Plane Extrusion).

Material is Plain Carbon Steel.

Cart Wheel Spacer

This item fits between the

Wheel and the Wheel Mount. Design this part so that the wheel does

not interfere with the Cart.

Cart Axle Hub Cap

This item fits on the end

of the axle. Design this part using a sketch and the Revolved Boss

Base feature.

Cart Front Support

This item will be designed

in class using the Loft Feature.

More details will follow

before class on Tuesday.

|

- |

|

|

|

|

-

| Due

this week:

Final

drawings of your Final Project design printed on A or B sized sheets in

the lab. |

We will go over the test

briefly on Tuesday and will work on the Final Project both on Tuesday and

Thursday.

|

- |

|

|

|

|

-

Final Project presentations

will be during the Final examination time slot set aside for our class

on Tuesday at 6pm. For those that want to start early I will be in

the lab at 5pm if the lab is available. Please plan on staying for

all of the presentations.

The procedure for your presentation

will be the following:

-

Prior to the class starting,

each student will load their folder of presentation materials and their

SolidWorks files of their project on the desktop of the instructor's computer.

-

Your folder needs to have your

name on it so I can download it and take it home for grading.

-

Once the files are loaded on

the instructor's computer we will start the presentations.

-

Presentations

-

For those that are presenting

during the 5 o'clock hour we will take a break at about 5:50 so that the

rest of the class can load their folders onto the instructor's computer.

-

A presentation schedule is available

at the Student Resource link above.

-

For additional information on

the Final Project visit the links at the Student Resources link above.

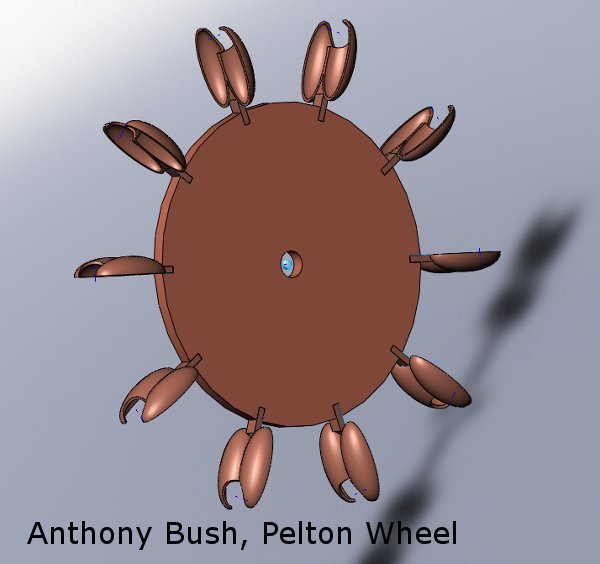

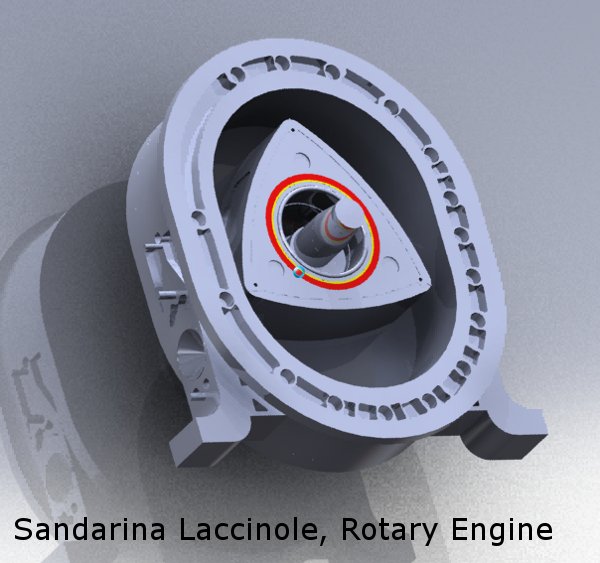

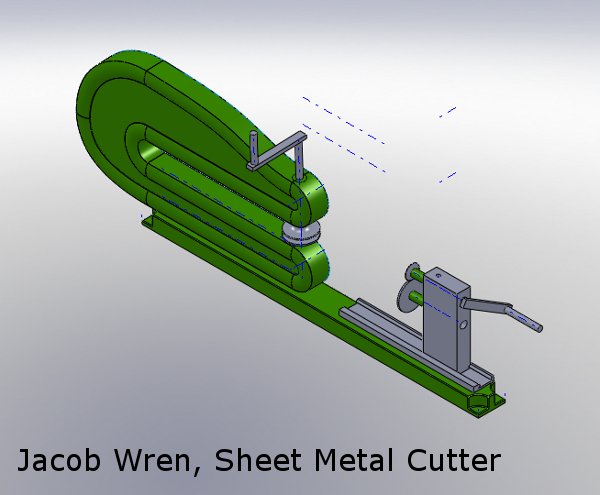

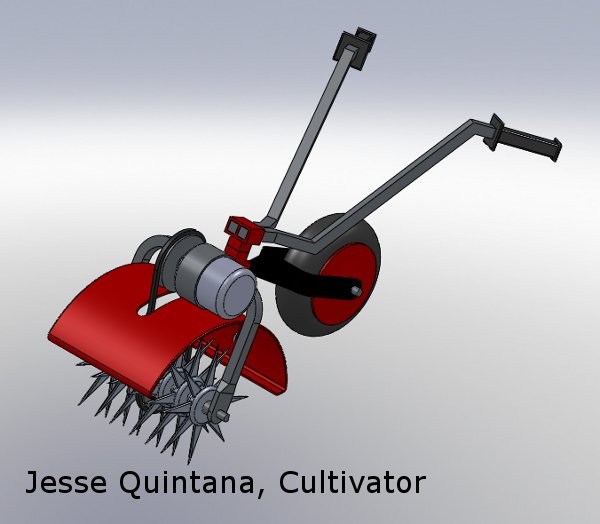

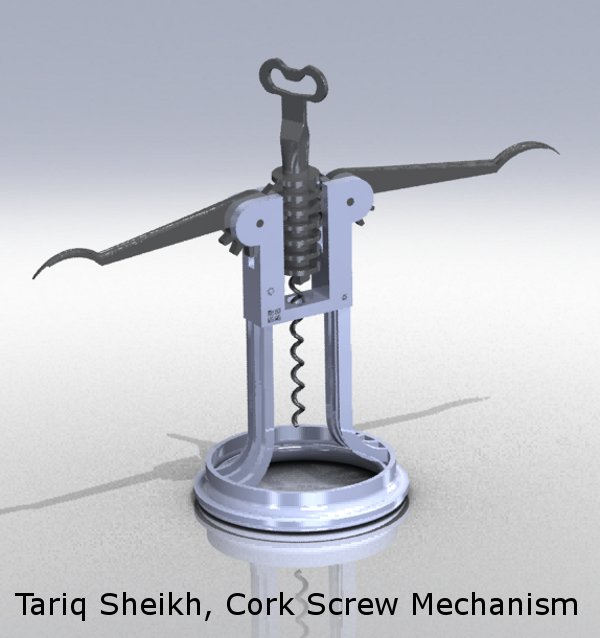

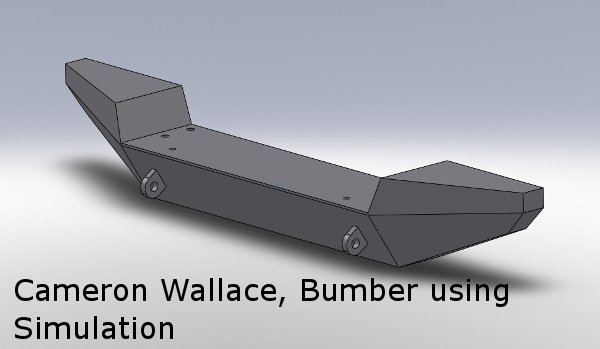

Below are some images and videos

of your completed projects:

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

- |