|

|

- |

|

|

|

|

-

Click on the following links:

Trailer

for the Movie "21"

Interview

with Jon Hirschtick, Founder of SolidWorks

Scibd

Biography of Jon Hirschtick, Founder of SolidWorks

Jon

Hirschtick explains his Black Jack Team techniques

Jon

Hirschtick on the Movie "21"

-

| Week

1:

Read

the introductory sections of both textbooks. Also read and model

Lessons 1&2 in the SG textbook and read and model Project 1 in the

ED textbook up to page 1-64. |

|

- |

|

|

|

|

-

| Week

2:

An evaluation

of 2 of the 4 models that we have modeled so far will be on Tuesday.

Refer to the guidelines below and the Grade Sheet link above and click

on the Week 2 tab for the grading criteria.

Call

me if you have any troubles, do not come to class unprepared!

Assignments

include: The Guide, Axle, Shaft Collar and Flat

Bars in the ED book. Tutor1 and the Door in the SG book.

See

below. |

-

For Tuesday we will have

an evaluation of 2 of the 4 models that we have modeled so far. The

first one will be the Plate with the other either the Receptacle Plate

or Switch Plate. The evaluation criteria will include:

-

Completeness, models are finished

with all of the features shown in the examples or in class. (5 points with

1/2 point off for each missing feature).

-

Dimensions, I will be looking

for proper dimensions on your sketches (2 points with 1/2 point off for

each missing dimension).

-

Fully Defined, your model sketches

will be fully defined (lines are black) (1 point with 1/2 point off for

each under defined line).

-

Feature Names, rename features

to better describe what that feature does (1 point with 1/2 point off for

each unnamed feature). See example below.

-

Origin, the origin will have

to be somewhere placed specifically in the model either in the center of

your object or where the examples in the book show it to be located (1

point).

-

Extra credit, 1/2 point for

each fully defined feature or element.

Assignments:

Complete the Guide, Axle,

Shaft Collar and four configurations of the Flat Bars

(3, 5, 7 and 9) in the ED book. A demonstration on configurations

will be held in class.

Complete Tutor1 and

the Door in the SG book.

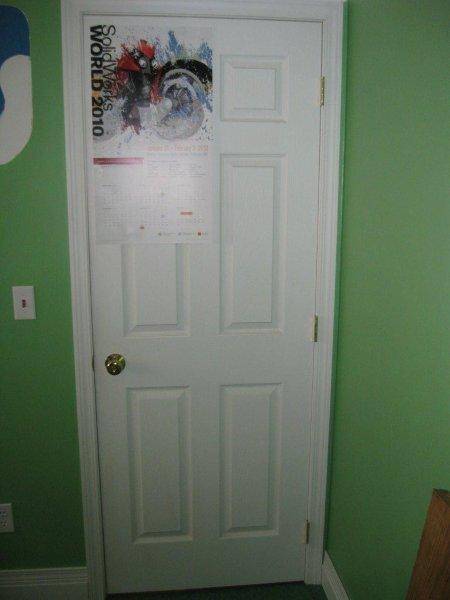

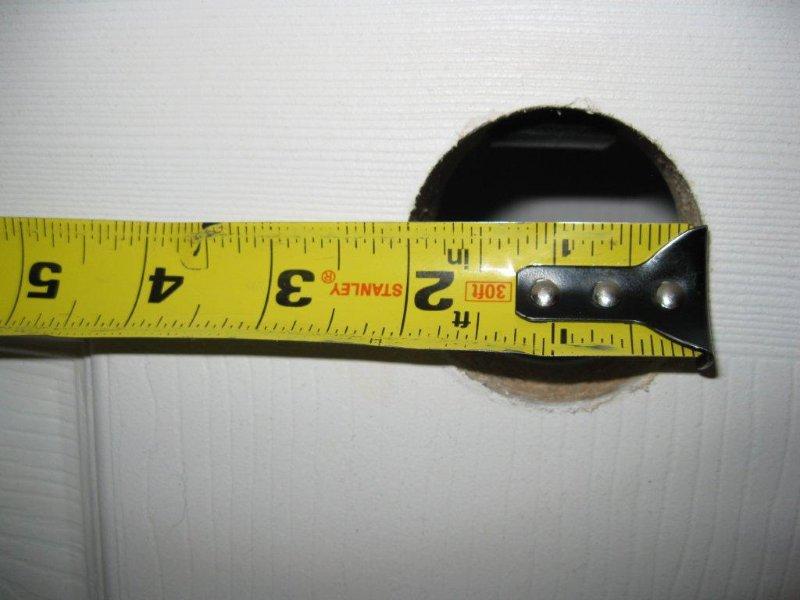

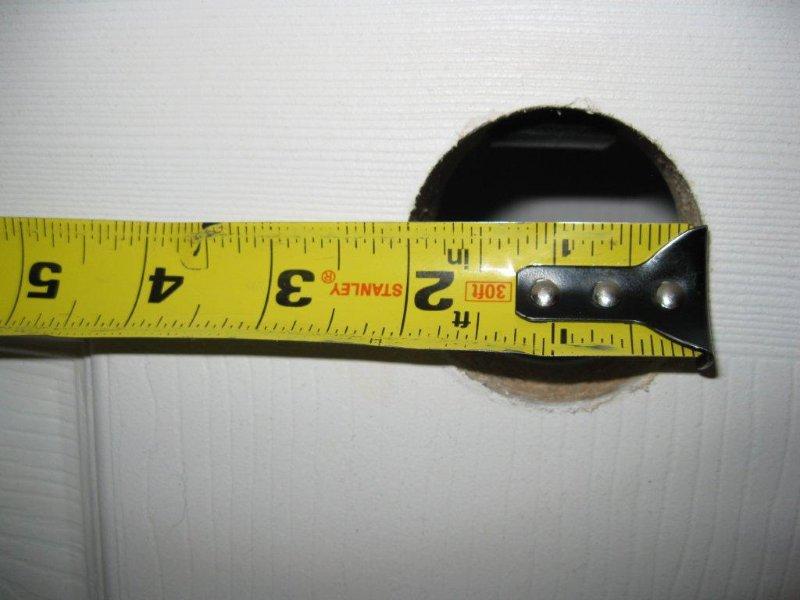

Model a door, any door you

like, in a manner you see fit with at least one door panel feature.

A demonstration on the Sweep Cut feature, which may be used to cut door

panels, will be shown in class.

Information on the construction

of a door follows in the images below, my door was 1-3/8" thick:

-

-

-

-

-

-

-

|

- |

|

|

|

|

-

| Week

3:

Assignments

this week include 5 assemblies to graded in class next Tuesday. Check

the class schedule for details.

A few

students were modeling the Rod from Project 1 in the ED book.

This model is available for download on the Student Resource page for use

in Project 2. |

-

|

- |

|

|

|

|

-

| Week

4:

We will

cover Drawings this week. As demonstrated on the first day of class

SolidWorks provides a comprehensive way to demonstrate your designs in

a 2D format (drawings on paper). The first task on Thursday will

be to update our new drawing templates using the Tutor2 drawing that we

did in class on Tuesday. Use these updated templates for the drawings

due this week and for the rest of the quarter. For the assignments

this week, follow the Class Schedule. Start with the SG assignments

first then the ED assignments.

All of

the drawing assignments will be due on Friday of Week 5 by 5pm in the "box". |

-

|

- |

|

|

|

|

-

| Week

5:

Your

first examination will be on Tuesday, including both a written examination

as well as a modeling exercise including parts and an assembly. See

details below.

Drawings

will be due in the "box" by Friday of this week (in lieu of the usual Tuesday

deadline). They will be graded over the weekend and returned on Monday.

Check the "Drawing Guidance" section in the Student Resource section of

the website for grading information.

The grades

for your first examination will be posted this weekend as well as your

drawing assignments due on Friday. A letter grade for the quarter

will also be assigned giving you an opportunity to see where you stand

in class if I had to grade you as of this week. I will be doing this

every week now until the end of the quarter. |

-

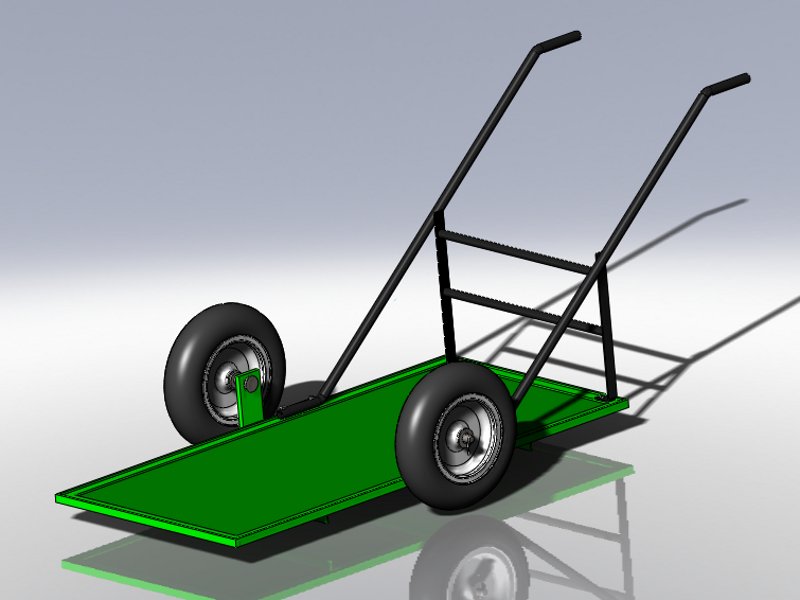

Examination Details:

In the 2 examinations for

this class you will be modeling the parts and putting them together in

the assembly of a Low Profile Garden Cart similar to the one in the image

below:

For the first examination

on Tuesday you will model the following parts and then put them into an

assembly named Low Profile Cart:

-

Angle Support (2) (model

before class, see information below)

-

Wheel Support (model

before class, see information below)

-

Base Frame (with 2 configurations,

Bottom Frame and Top Frame)

-

Frame Floor (model before

class per the information given in class)

For the modeling portion of

the examination you will utilize the following design elements including:

-

2 part Configurations on the

Base

Frame

-

Tool Box nuts, washers and bolts

in the assembly

-

2 display states in the assembly,

one green and the other a color plus other attributes of your choice.

Some of the parts will be modeled

before class on Tuesday with information supplied in class or described

below.

The evaluation for the modeling

portion of this exam will consist of the following:

-

Evaluation of your assembly

similar to what we have been doing in class.

-

Include the 2 display states

mentioned above

-

Fully defined

-

Evaluation of a part similar

to what we have been doing in class.

-

Include a part modification

-

A Part Drawing of the Base

Frame (Bottom Frame configuration), to be printed by 7:30pm

on Tuesday.

-

Include all of the elements

shown in class for the Tutor2 drawing and in the templates that

we worked on.

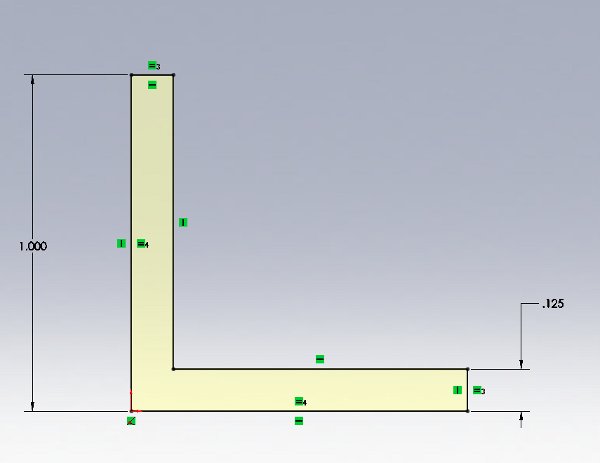

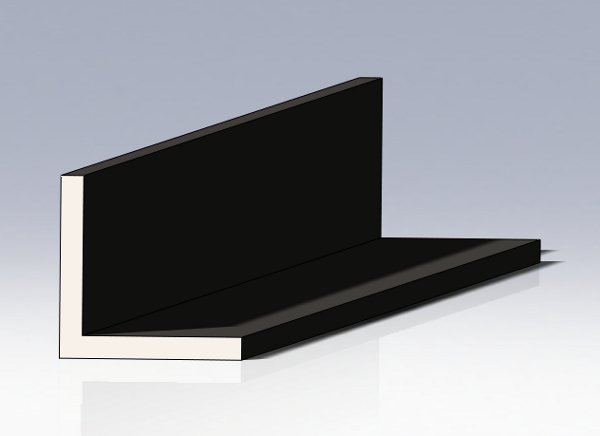

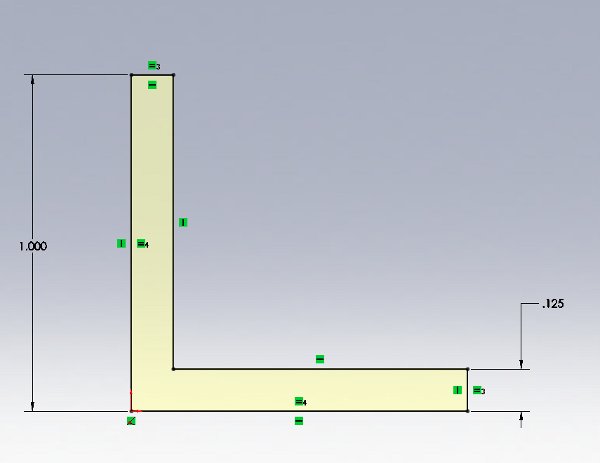

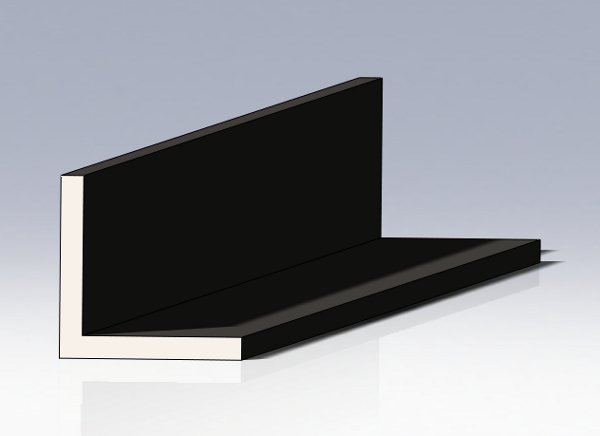

The Angle Support,

model the following part:

-

Material: 1023 Carbon Steel

Sheet (SS)

-

Sketch on the Right Plane in

inches

-

Mid Plane Extrude to 23 inches

-

Hint, draw 2 rectangles and

use the Trim sketch tool

-

Notice the location of the Origin

and Sketch Relations

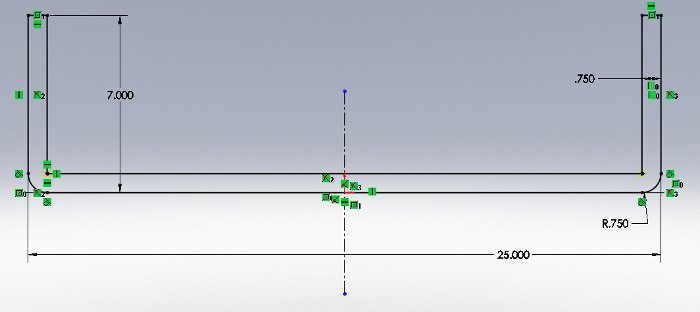

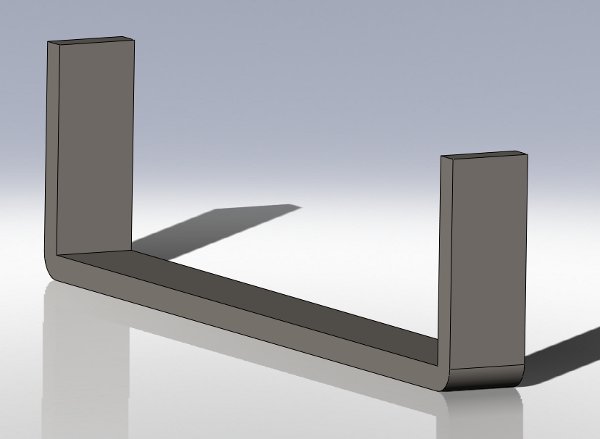

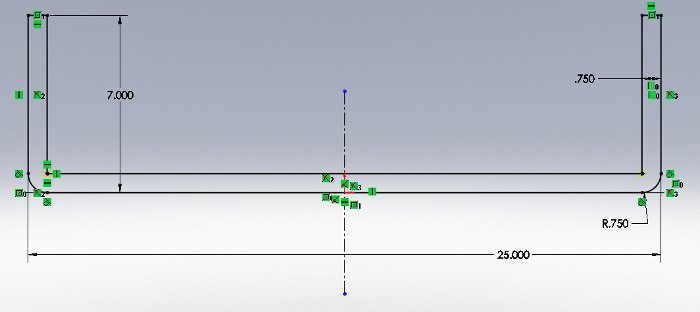

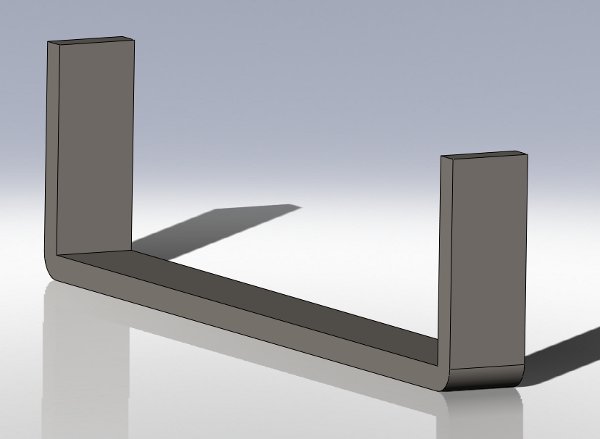

The Wheel Support,

model the following part:

-

Material: 1023 Carbon Steel

Sheet (SS)

-

Sketch on the Front Plane in

inches

-

Mid Plane Extrude to 3 inches

-

Hint, draw a Construction Line

vertical from the Origin then sketch on one side of this line using the

Mirror sketch tool to complete the other side.

-

Notice the location of the Origin

(center on the bottom line) and the various Sketch Relations.

|

- |

|

|

|

|

-

Week

6:

What

is due on Friday by 5pm:

Image

file of the Candle Stick assembly. (send by email).

Image

file of the Mug (send by email).

Drawing

of your Mug design (in the box (see details below)).

What

is due next Tuesday in class:

Evaluation

of the your Motion Study. |

Those

that missed the evaluation of your exam design assignment (the Low Profile

Cart assembly and the Wheel Support part) during the examination

will have only one additional opportunity for grading on Tuesday, May 4

during class. I will not be taking any points off since extra

credit had been applied to those students who got their assignments done

by the end of the exam.

Nothing

is due on Tuesday. We will go over in class on Tuesday the Candle

Stick and Mug design assignments. On Thursday we will

cover the Threaded Fastener assignment and the Motion Study.

Think

about your Final Project this week. An abstract will be due

iterating your ideas next Tuesday. Run any ideas by me first.

Check previous years' Website for ideas. Check out the Final Project

Abstract link at the Student Resources link. |

Assignments include (due

on Friday by 5pm):

-

Image file of the Candle

Stick assembly using PhotoWorks.

-

High resolution option.

-

Must have a scene and lights.

-

800 x 600 pixels only.

-

Image file of your Mug

design using PhotoWorks.

-

2 points allocated for creativity

-

Extra credit for extra features

-

High resolution option.

-

Must have a scene and lights.

-

800 x 600 pixels only.

-

10 points extra credit for a

similar design using the revolved and sweep features (bowls, wine glasses,

cups, trays, top, lamp, etc...)

-

Drawing file of your Mug

design.

-

A sized sheet

-

Display the following views:

-

Front View showing Hidden Lines

Visible HLV

-

Top View with Hidden Lines Removed

HLR

-

Right View with Hidden Lines

Removed HLR

-

Isometric View with Shaded With

Edges SWE

-

Add views titles under each

view

-

Fill the usual values in the

Title Block (as iterated in Project 3) including:

-

your name

-

part name

-

file name

-

company name

-

units of measure

-

dimensioning standard

-

confidentiality statement (filled

in with your company name)

-

Include all appropriate dimensions.

|

- |

|

|

|

|

-

Week

7:

| What

is due on Tuesday:

Evaluation

of your Motion Study of the Linkage Assembly, instructions

below.

What

is due on Friday:

A drawing

of the Bracket 100 from the Pulley Assembly will be due in

the "box" along with your Final Project Abstract. |

Think

about your Final Project. An Abstract is due on Friday, however,

run any ideas about what you would like to do for your project by me first.

Check previous years' Website for ideas. Check out the Final Project

Abstract link via the Student Resources link below.

We will

start our Threaded Fastener assignment in class on Tuesday and continue

on Thursday. This will be evaluated next Tuesday. |

The Linkage Assembly Motion

Study grading criteria:

-

Create a platform for the air

cylinder

-

Animation, instead of Basic

Motion analysis

-

Must have at least 3 motors.

-

2 rotational motors

-

1 linear motor

-

extra credit for any of the

other motion driving elements

-

No default settings

-

Duration at least 10 seconds

-

Turn on and off motors at different

times

-

Can not have errors

-

Motion has to make sense

-

Create a video

The drawing for the Bracket

100 from the Pulley Assembly shall have the following requirements

along with the usual Title Block elements, View Titles and other features

required on previous drawings:

-

A sized sheet

-

Dual unit dimensions

-

Display the following views:

-

Front, Top and Right Views showing

Hidden Lines Visible, HLV

-

Isometric View with Shaded With

Edges, SWE

-

Front View will be the view

with the face that is coincident to the face of the assembly with the coordinate

system on it, which will be parallel to your screen.

-

Right View shall have centerlines

inserted for the holes in the base with dimensions from these lines.

-

Include an additional view besides

the standard 4 views with a dimension(s).

-

Be certain to fill the usual

values in the Title Block (as iterated in Project 3) including:

-

your name

-

part name

-

file name

-

company name

-

units of measure

-

dimensioning standard

-

confidentiality statement (filled

in with your company name)

Include all appropriate dimensions.

|

- |

|

|

|

|

-

Week

8:

| What

is due on Tuesday:

Evaluation

of your Threaded Fastener assignment, Pulley Assembly and

the Chisel, Bottle and Screw Driver.

What

is due on Friday:

Two GD&T

drawings. |

We will

cover the procedures of the Spur Gear assignment this week as well

as a couple of projects related to Geometric Dimensioning and Tolerancing

(GD&T). |

Information on the Spur

Gear assignment can be found at the Student Resources section of the

website.

|

- |

|

|

|

|

-

Week

9:

What

is happening on Thursday:

Examination

2.

What

is due on Friday:

Two

GD&T drawings. One on the Axle 40 and the other on the

Bracket

100. Details below.

Final

Project preliminary part and assembly drawings. |

|

On Tuesday we will modify

the drawing that we have done for the Bracket 100 part and create a new

drawing for the Axle 40 part (from the Pulley Assembly assignment from

Week 7) related to GD&T. These drawings will be due in the "box" by

Friday. Check out the Student Resources section of the Website for

additional information.

For the Axle 40 part

create a drawing and add the usual dimensions and drawing items plus the

following GD&T items:

-

Datum A on the axis of the axle

-

Datum B on the far left face

of the axle

-

Change the outside dimension

to 20 with a Bilateral Tolerance of no more than 20 but up to 0.10 millimeters

less

-

Add a Feature Control Frame

on this dimension stating a Total Runout tolerance of 0.05 millimeters

referencing Datum A

-

Change the inside dimension

to 16 with a Bilateral Tolerance of no more than 16 but up to 0.10 millimeters

less

-

On the 56 millimeter dimension

add a Feature Control Frame stating parallelism with a tolerance of 0.10

millimeters at the MMC referencing Datum A

-

On the 86 millimeter dimension

add a Feature Control Frame stating perdendicularity with a tolerance of

0.10 millimeters at the MMC referencing Datum B

For the Bracket 100

part

drawing modify the drawing and add the following GD&T items:

-

Datum A on the bottom face of

the part

-

Datum B on the axis of the axle

hole

-

Datum C on the outside vertical

face of the triangular axle mount.

-

Modify the dimension on the

hole for the axle to have a Bilateral Tolerance of up to 0.05 millimeters

more but no less than 16 millimeters

-

Add a Feature Control Frame

with 2 lines on this dimension stating that the hole needs to be parallel

to Datum A with a tolerance of 0.05 millimeters at the MMC and on the second

line, perpendicularity to Datum B and Datum C with a tolerance of 0.05

millimeters at the MMC.

-

Modify the dimensions on the

10 millimeter mounting holes adding a Symmetric Tolerance of plus or minus

0.10 millimeters.

-

Add a Feature Control Frame

on this dimension stating that the position of the mounting holes have

a tolerance of 0.10 millimeters at the LMC referencing Datum A and Datum

C

On Thursday we will have our

Examination 2.

Examination Details:

Information on various parts

needed for the Low Profile Cart assembly follow below:

The parts include the following:

Floor Frame (Exam 1)

Base Frame, Top Frame Configuration

(Exam 1)

Base Frame, Bottom Frame

Configuration (Exam 1)

Angle Support (Exam 1)

Wheel Support (Exam 1)

Wheel (see below)

Tire (see below)

Wheel-Tire sub-assembly

(see below)

Handlebar (see below)

Handlebar Support Assembly

(given, see below)

Handle (see below)

Axle with Loft Features

(part of Exam 2)

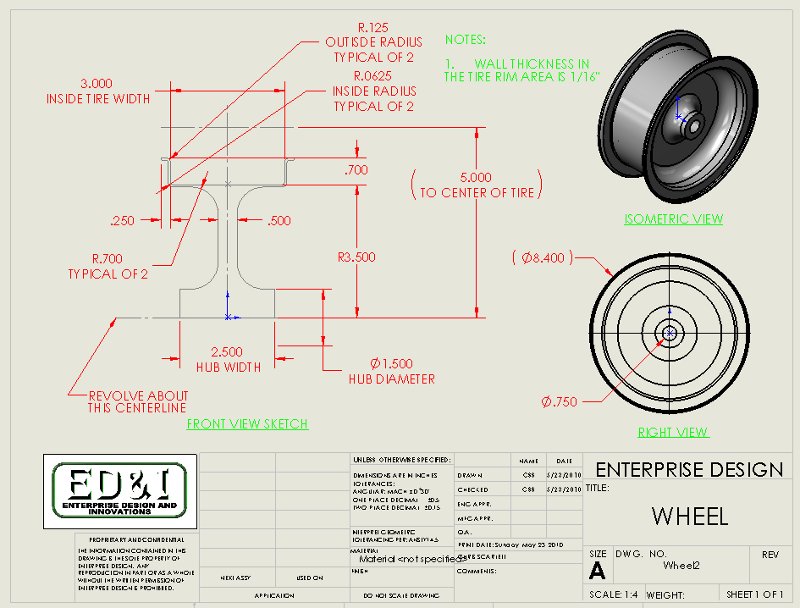

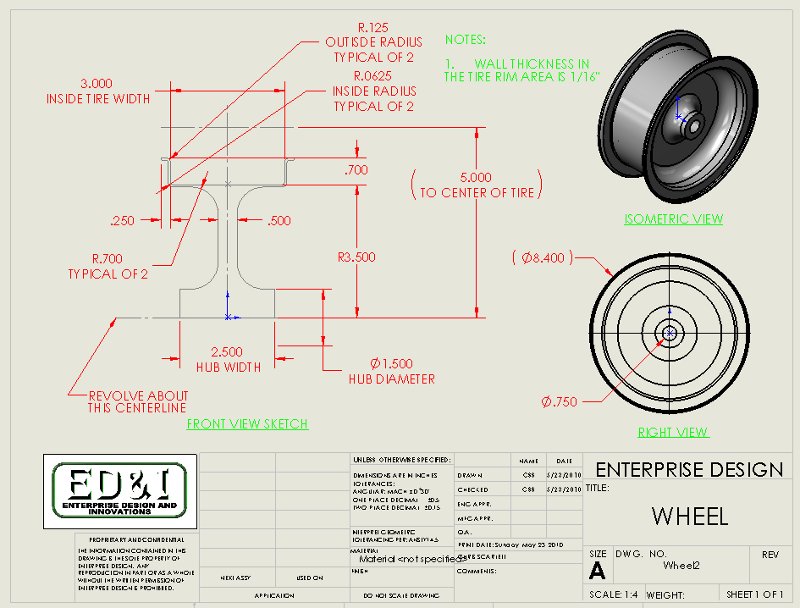

Wheel, model the

following part:

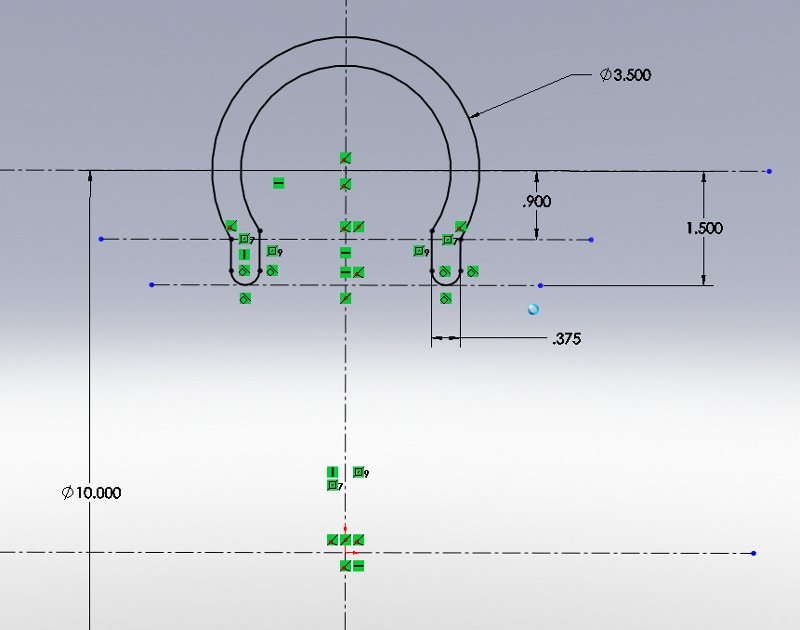

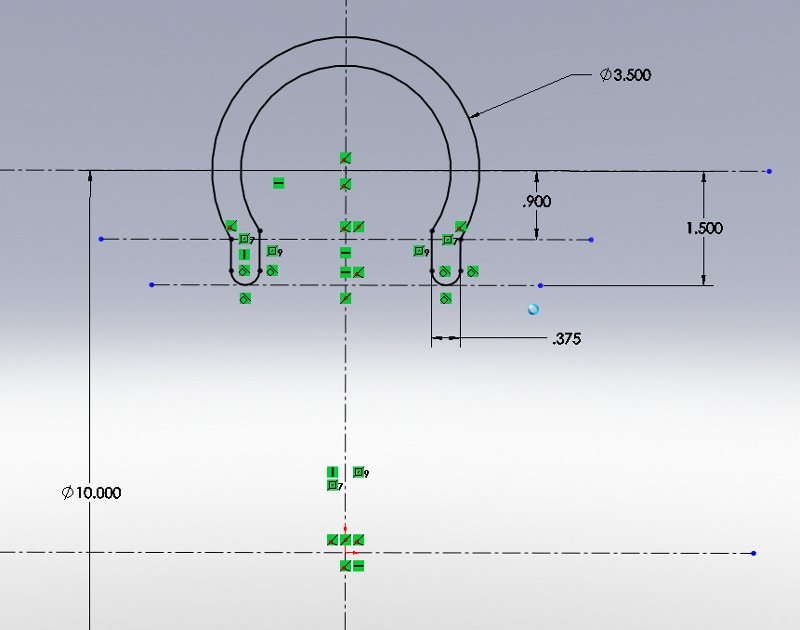

Tire, model the

following part:

-

Material: Rubber

-

Sketch on the Front Plane in

inches

-

Hint, Tire thickness is 0.375"

-

Sketch the reference geometry

first, the four centerlines with dimensions

-

Sketch the outside arc first,

the center of the arc is vertical of the Origin and on the 10 inch diameter

centerline

-

Use the mirror sketch entity

for the tire rim portion

-

Revolve Boss/Base

-

Notice the location of the Origin,

same location as in the Wheel (this is important for the sub-assembly)

-

Add treads for extra credit

-

We will cover this model

in class on Tuesday

Wheel-Tire, assemble

the following assembly:

-

Create an assembly named Wheel-Tire

-

Insert both parts "fixed" to

the Origin.

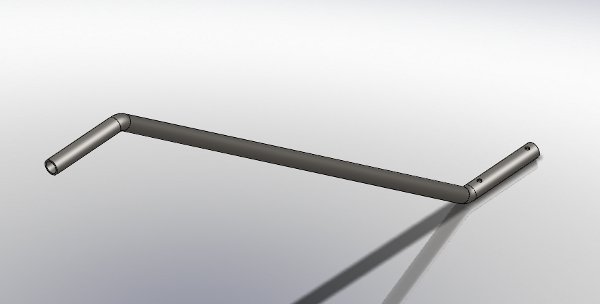

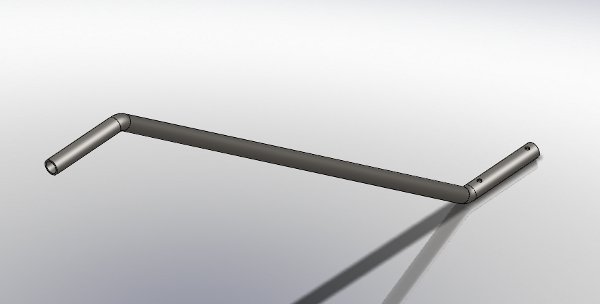

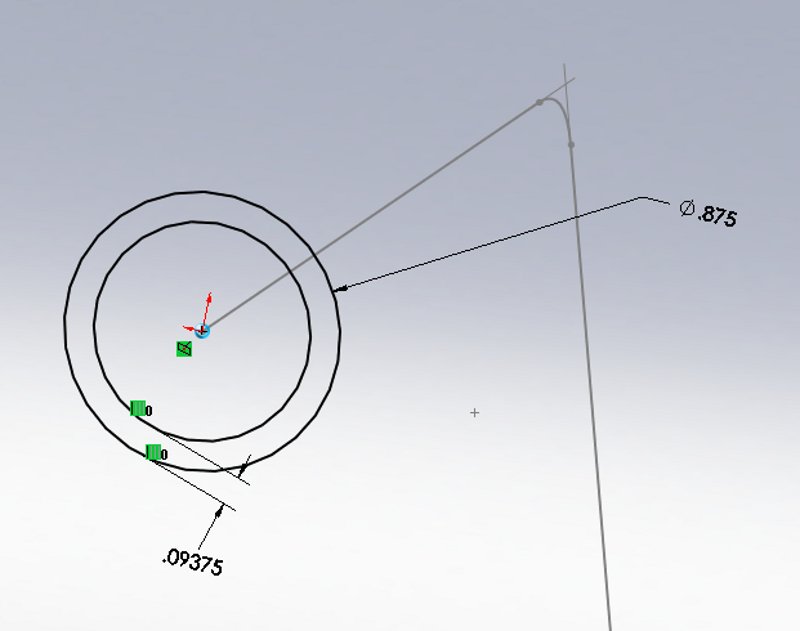

Handlebar, model

the following part:

-

Material: 1023 Carbon Steel

Sheet (SS)

-

Swept Boss/Base

-

Sketch the path on the Right

Plane

-

Insert a reference plane at

the end of the path and sketch the profile as shown below

-

The wall thickness is 3/32"

-

Insert a reference plane so

that it is parallel to the Top Plane and tangent to the front end of the

Handlebar for the Hole Wizard.

-

Use the Hole Wizard on the recently

inserted plane using the same settings and distance as it is on the Base

Frame

-

The first Hole Wizard hole is

1/2" from the front end of the Handlebar

Handlebar Support Assembly,

download the following assembly and parts:

Download

Handle, design

your own part

-

Material: of your choice

-

Must contain Loft Features

-

Must fit over the handlebar

More information later

|

- |

|

|

|

|

-

Week

10:

| Work

on your Final Project parts assemblies and drawings this week. Ample

help will be available.

Final

Project part and assembly drawings, second round, are due in the "box"

on Friday. |

|

Hand in your Part and Assembly

Drawings by Friday in the Box.

-

These will be your final drawings,

worth 15% (30 points) of your Final Project grade and should include the

following:

-

Sheet size of your choice.

-

All of the elements that have

been required throughout the quarter.

-

Assembly drawings should have

basic dimensions only

|

- |

|

|

|

|

-

Hand in your Part and Assembly

Drawings after the Final project Presentations today in the Box.

-

These will be your final drawings,

worth 15% (30 points) of your Final Project grade and should include the

following:

-

Sheet size of your choice.

-

All of the elements that have

been required throughout the quarter.

Assembly drawings should

have basic dimensions only

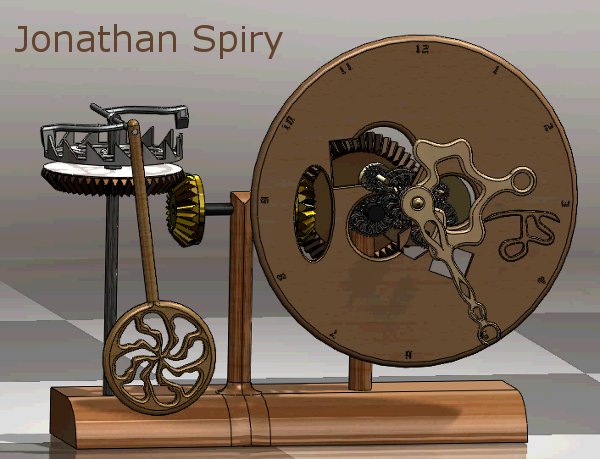

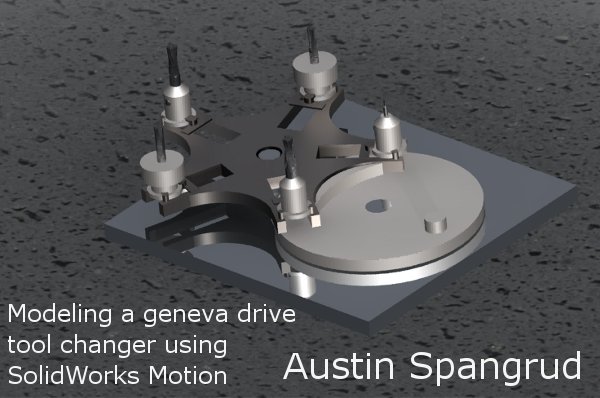

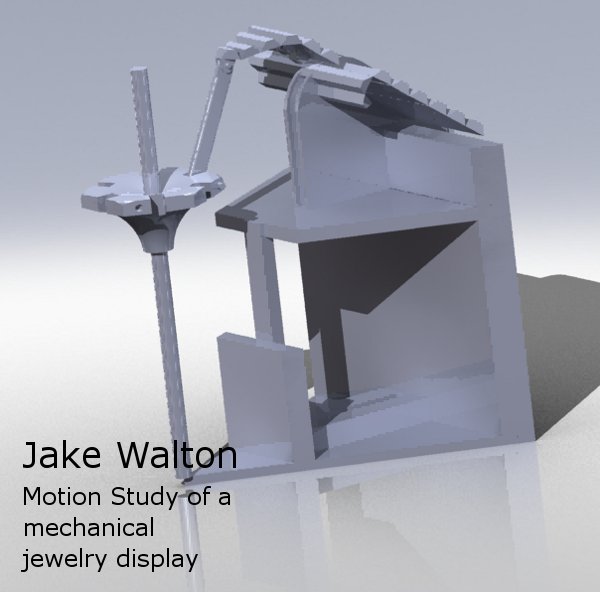

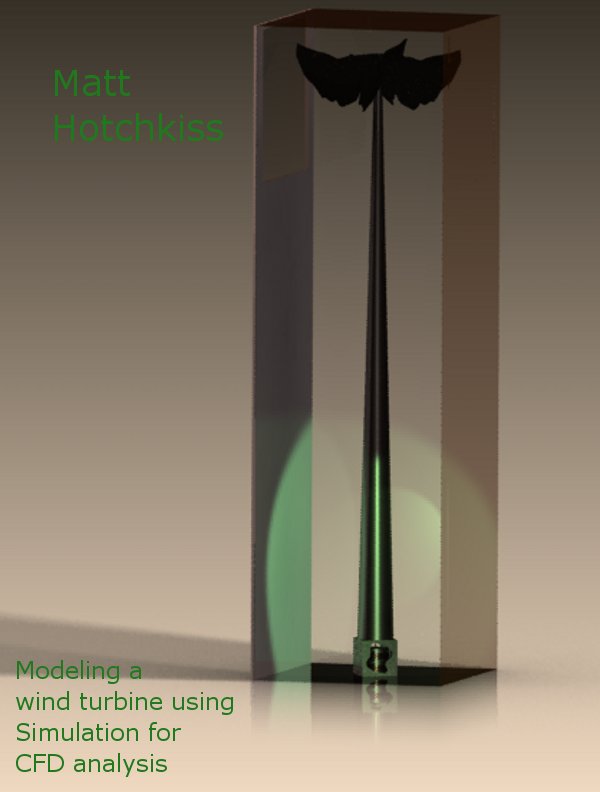

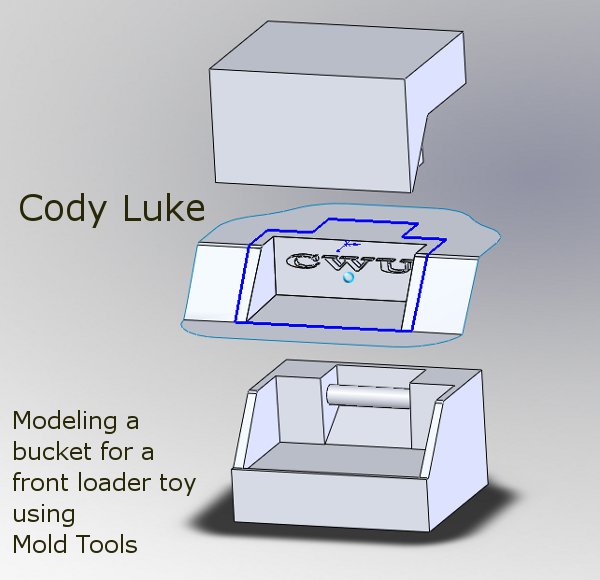

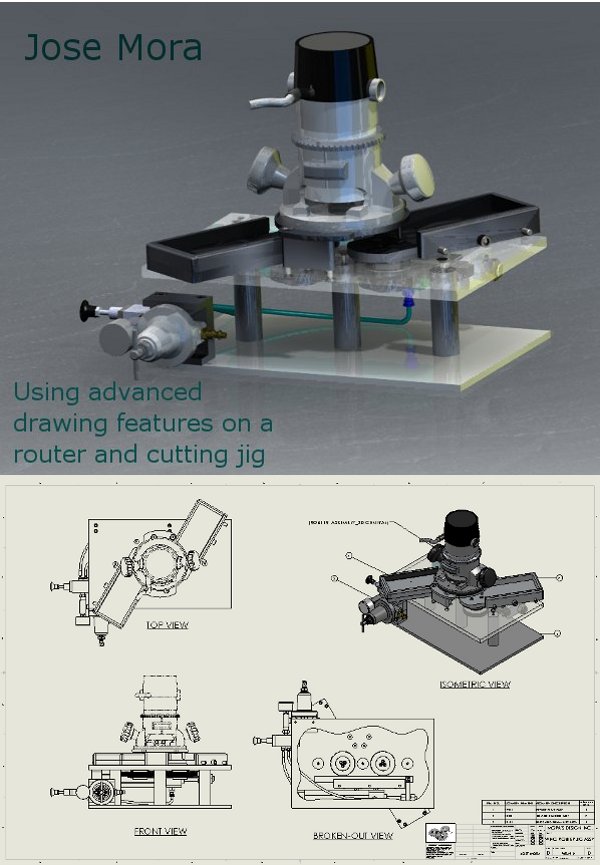

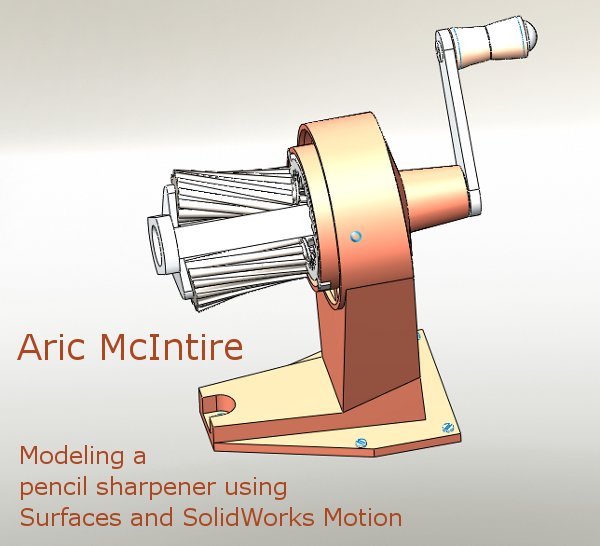

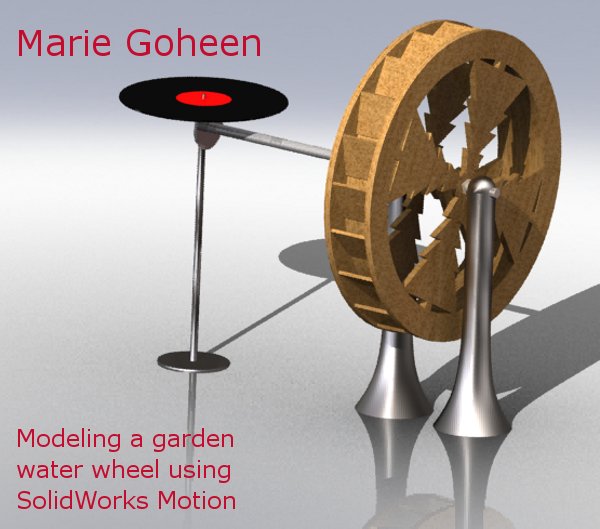

Below are some images and videos

of your completed projects:

click on the image above

for a video

click on the image above

for a video

click on the image above

for a video

click on the image above

for a video

-

-

|