ParabaRail

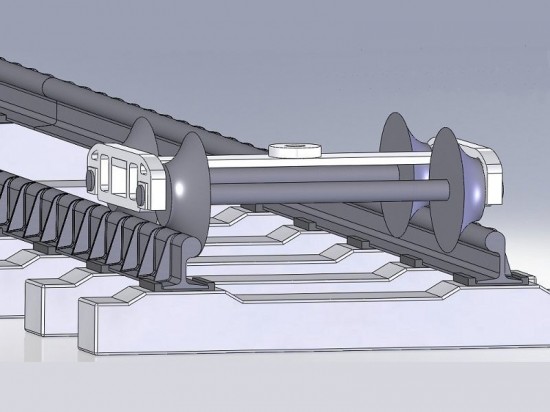

The idea behind this was to develop a way for rail cars to lean into the center of a curve as a means of allowing the force of gravity to counteract the centrifugal force. Typically railroads will have a super elevation engineered into them for a ceertain velocity. When traveling at that velocity, passengers and freight will not be forced into the walls of the moving car when going around a curve. However, if a car were to travel at a faster or slower speed than the super elevation was designed for, then passenger discomfort and freight shifting may result with people and freight shifting to one side or the other of the car. With this new rail wheel concept, some super elevation may be taken out of railroad construction. The centrifugal force will be counteracted on by the force of gravity when the car enters into a curve. The faster the car is moving around the curve the more the car will lean to the inside. Many mechanisms (mostly complicated ones) have been developed over the years to try and mitigate this problem; this rail wheel concept solves the problem very simply. The mechanism behind this design is that when the centrifugal force exerts itself as a car enters a curve , the force will pull the car and therefore the truck (car wheel assembly) to the outside of the curve causing the exterior wheel to climb up the rail and the interior wheel will to step down. When this happens the contact perimeter of the exterior wheel will increase while the contact perimeter on the interior wheel will decrease (like having two different sized wheels on the same axis, one small one large) this will cause the truck to lean to the inside allowing the force of gravity to counteract and balance the centrifugal force. This is a concept worthy of further development.