|

- |

|

|

|

|

-

| Week

1:

Design

Assignments due this week:

None

this week but come to the first class of Week 2 prepared by starting the

Design Assignments listed in this section below and in the Week 2 section

following.

Announcements:

Please

purchase download or otherwise acquire the following books listed below

for use in this class:

Engineering

Design... (ED)

oooo

Available

at the bookstore oooooooooooo

|

The

Ultimate GD&T Pocket Guide (UG)

Available

at the bookstore

ooooo |

Student's

Guide...

(SG)

Available

on the Student Resources page

|

d

Read

and practice ahead:

Begin

reading the engineering design book (ED) beginning with the introduction.

Then start with Project 1 designing the Plate following the steps

involved. Continue on with the Rod and the Guide.

Begin

reading the student guide (SG) from the introduction through Lesson 1 then

design the Box in Lesson 2 following the steps involved.

There

will be an evaluation on the first day of class next on these assignments.

|

Out

of Class Design Assignment details:

-

ED Book

-

Start the Plate in Project

1

-

Create the various part template

files (see the video links below)

-

SG book, Lesson 2

-

VD the Junction Box video,

see

links below.

Instructional

Videos:

|

- |

|

|

|

|

-

| Week

2:

Design

Assignments due:

On the

first day of class this week come to class with the completed assignments

from Week 1 in preparation for your In Class Evaluation (ICE). See

details below. |

In

Class exercises and assignment details:

-

In Class Evaluation (ICE) (2

items). Click here for

your Week 2 ICE Grading Criteria (coming soon) print this out, fill

in the needed information, follow the instructions and hand it in at the

end of the evaluation. On the first day of class this week we will have

an evaluation of the models completed so far from Week 1, the Plate,

Box and Junction Box. The evaluation criteria will include:

-

Junction Box (10pts)

-

Completeness with symmetry (2pts)

-

Fully defined sketches with

dimensions (4pts)

-

Extrude, Feature Fillet, Shell,

Extrude Cut for hole (1pt each)

-

Extras and errors

-

Mounting Plate (10pts)

similar to the Plate in the ED book

-

Completeness with symmetry (2pts)

-

Correct starting plane (1pt)

-

Fully defined sketches with

dimensions (4pts)

-

Extrude, Feature Fillet, Extrude

Cut for hole (1pt each)

-

Extras and errors

-

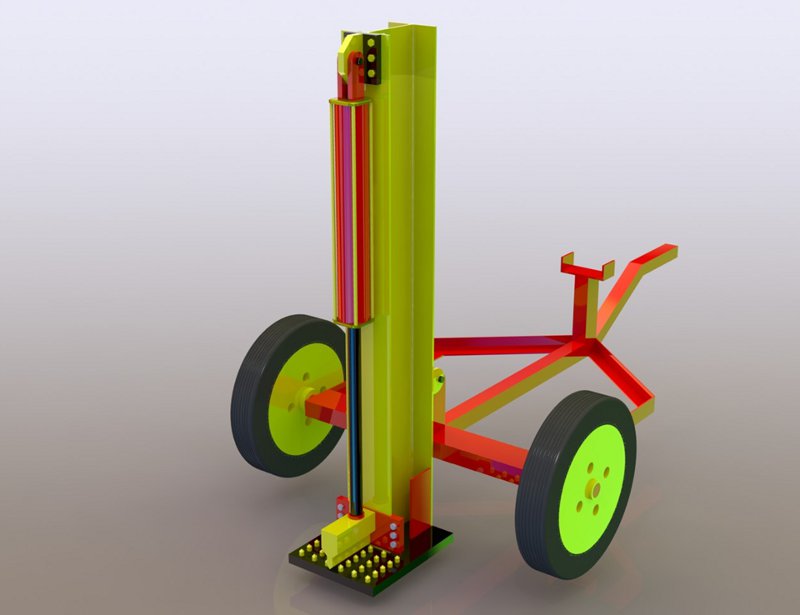

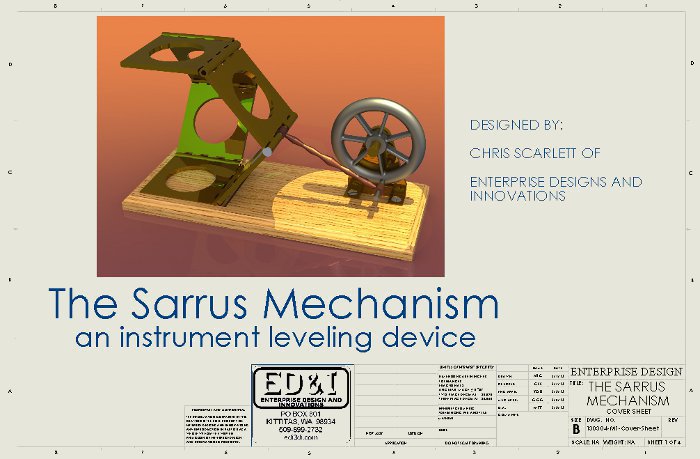

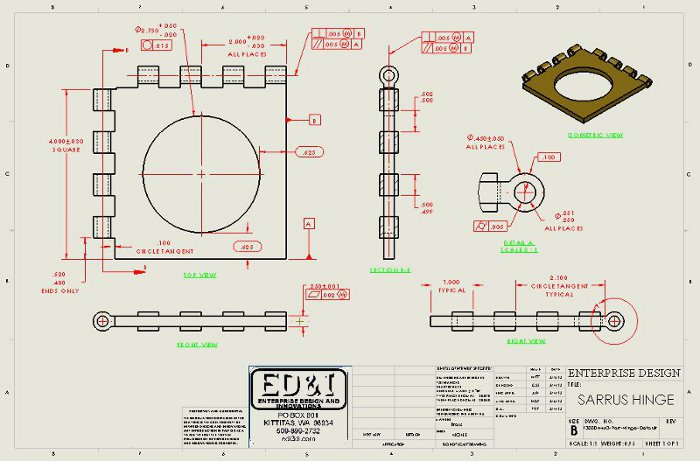

The Sarrus Mechanism Demonstration

click on the following link

for a zip file of the parts and assembly Sarrus

click on the following links

for pdfs of the part drawings.

Base

Plate

Hinge

Wheel

Mount

Wheel

Push

Rod / Pin

Out of

Class Design Assignment details:

-

Complete the Plate, start

the Rod and

Guide

in Lesson 1

-

The exercises from the end of

Project 1 on the Class Schedule

SG book, Lesson 2

VD Junction Box (and

the Section videos for the ED book exercises)

Instructional

Videos:

|

- |

|

|

|

|

-

| Week

3:

Design

Assignments due:

On the

first day of class this week come to class with the completed assignments

from Week 2 in preparation for your In Class Evaluation (ICE). See

details below. |

In

Class exercises and assignment details:

-

In Class Evaluation (ICE) (3

items). Similar to last week: Click

here for your Week 3 ICE Grading Criteria, print this out, fill in

the needed information, follow the instructions and hand this in at the

instructor's desk at the end of the evaluation. On the first day

of class this week we will have an evaluation of the models completed from

Week 2. The evaluation criteria may include:

-

New Part 1 (10pts)

-

Completeness with symmetry (1pt)

-

Correct starting plane (1pt)

-

Material 6061 Alloy (1pt)

-

Fully defined sketches with

dimensions (1pt)

-

Extrude, Feature Fillet, Shell,

Extrude Cut for hole, Hole Wizard (1pt each)

-

Find the Mass, 4 units after

the decimal (2pts)

-

Extras and errors

-

Mystery Part 1, already completed,

to be announced during the ICE (10pts)

-

Completeness with symmetry (1pt)

-

Correct starting plane, material

AISI 304 (1pt)

-

Fully defined sketches with

dimensions (1pt)

-

Save the file then resave it

with the following name TBA (1pt)

-

Modify various dimensions, TBA

(1pt each)

-

Find the Mass, 3 units after

the decimal (1pt) Center of Mass x, y and z (2pts)

-

Extras and errors

-

Mystery part 2, already completed,

to be announced during the ICE (10pts)

Out of

Class Design Assignment details:

-

Assembly Models. This

is a graded assignment for this week. On Thursday I want a one paragraph

write up (in an appropriate engineering communication format) of what you

propose to model per the criteria below and printed before class (points

off for printing during class). The paragraph should include what

the assembly model will be called (such as Bar-B-Que, video game controller,

socket ratchet handle, conveyor belt, car, bike or similar items), what

it is used for, how it works and other descriptions then describe each

of the different part components that will be modeled and mated into the

assembly. I will discuss individually with you on Thursday what you

would like to model and give you some ideas on how to get started. Assignment

details follow:

-

Design at least 3 unique parts

with the expectation of assembling them for the next Design Assignment.

Parts in the assembly, other than the base, must be able to move, rotationally

or translationally (like a machine).

-

Base, one part has to be a base

feature to be fixed to the Origin in the assembly.

-

To have a round or rectangular

hole(s) or slot(s) or an extruded boss(es) for use as a reference for the

insertion of additional parts

-

Hole Wizard holes in the base

for mounting to some external structure

-

Parts1 and 2 (or more)

-

To be inserted on the base or

on one of the other parts

-

Must fit into the slots, holes

or bosses on the Base as described above

-

Fasteners, connectors, pins

and similar items are not appropriate parts for this assignment but can

be used.

-

Include the following features

on at least one of the parts above:

-

Fully defined sketches

-

Hole Wizard feature on a part

other than the Base

-

Linear or circular pattern

-

Include a Fastener from the

Toolbox in the Design Library into your assembly, in more than one location,

properly mated.

-

Feature using the Slot Sketch

Entity on a part

-

Evaluation:

-

A minimum level of complexity

is required for each part.

-

For the sketches of your parts

I will be looking for about 24 Sketch Relation groups, Dimensions and Reference

Geometry items on your most complex sketch.

-

For the Features of your parts

I will be looking for 6 Features or Bodies

-

3 parts will be considered for

full credit, the next 3 parts will be considered for half credit.

-

The combination of sketch elements,

features and parts will be added together, divided by 3 for a score with

a maximum of 36 points (20% more). From this score points will be

taken off for missed items in the section above or added to for extra effort

displayed.

-

Complete the Rod and

Guide

in

Lesson 1

-

Insert a cosmetic thread, of

the appropriate size, on both the front and back holes of the Rod.

-

The exercises from the end of

Project 1 on the Class Schedule

-

SG book, no exercises this week

-

SW Tutor1, in the SolidWorks

Tutorial (Getting Started) section of the Task Pane

-

Rearrange the Features so that

the front hole and the associated fillets are not influenced by the Shell

Feature (see image nearby).

-

VD The Meter Base

and

the Meter Cover and assembly below

Instructional Videos

|

- |

|

|

|

|

-

| Week

4: We will not have class on Tuesday of this

week. I will be attending the annual SolidWorks World conference.

Continue to work on your assignments from Week 4 and Week 5.

Design

Assignments due: None this week, look for

information in Week 5 soon. |

In

Class exercises and assignment details:

-

In Class Evaluation (ICE), none

this week.

-

On Thursday

of this week I will review your your Assembly Models in class. Similar

to last week, I will visit each of you and help you on your models prior

to the Week 5 In Class Evaluation. make certain that you have enough

modeled to make this help session meaningful. See the Week 5 section

bellow for additional information on grading.

Out of

Class Design Assignment details:

-

Complete the Guide-Rod assembly,

follow the book in Lesson 2

-

Ex 2.1, look for the files on

your book CD

-

Ex 2.8

-

use the Link created

in the "Configurations, Design Tables and Equations" videos listed below.

-

Make the Base symmetric,

front and back, left and right.

-

Make the link mounts symmetric

as well and forked.

-

Be creative with your designs.

-

VD The Configurations, Design

Tables and Equations videos below.

-

SW Tutor 2 follow the

instructions in the software tutorial.

-

Complete your Assembly Model

per

the criteria in Week 3.

Instructional Videos:

|

- |

|

|

|

|

-

| Week

5:

Design

Assignments due:

On the

first day of class this week come to class with the completed assignments

from Weeks 3 and 4 in preparation for your In Class Evaluation (ICE).

See details below. |

In

Class exercises and assignment details:

In Class Evaluation (ICE)

(3 items). Similar to previous weeks: Click here for your Week

5 ICE Grading Criteria, print this out, fill in the needed information,

follow the instructions and hand this in at the instructor's desk at the

end of the evaluation. On the first day of class this week we will

have an evaluation of the models completed from Weeks 3 and 4. Review

all of the videos that have been posted and listed on this site to ensure

that you have the following items covered properly for Week 5's evaluation.

The evaluation criteria may include:

-

New Part (20pts)

-

Completeness with symmetry (1pt)

-

Correct starting plane (1pt)

-

Material Aluminum (1pt)

-

Appearance clear (1pt)

-

Fully defined sketches with

dimensions (1pt)

-

Extrude, Feature Fillet, Hole

Wizard (1pt each)

-

Find the Mass, 4 units after

the decimal (3pts)

-

Extras and errors

-

New Assembly (using some modeled

parts from the previous weeks) (10pts)

-

Complete with all of the parts

(3pts)

-

Proper orientation of all parts

(1pt)

-

Base fixed to the origin

(2pts)

-

Properly mated, so that all

parts are fixed or fully defined (3pts)

-

Apply a scene (1pt)

-

Mystery Assembly (20pts)

-

Complete with all of the parts

(4pts)

-

Proper orientation of all parts

(1pt)

-

Base fixed to the origin

(2pts)

-

Properly mated, so that the

parts move as intended (3pts)

-

Assembly Model (30pts)

-

Criteria as defined in the Week

3 section above

Out of

Class Design Assignment details:

-

ED Book

-

Exercises 2.5 and 2.6, look

for the files on your book CD

-

SG Book

-

VD view the Sarrus Mechanism

assembly with mates, Toolbox items and an Exploded View configuration.

Apply these techniques to your Assembly Model project. See the video

section below.

-

Assemble your Assembly Model

using

appropriate mates, Toolbox items and an Exploded View configuration.

-

Assemble the 3 or more parts

of your design into a SolidWorks Assembly. Mate these using the requirements

listed below. The parts in your assembly, other than the base, must

be able to move, rotationally or translationally (like a machine).

Apply mates to achieve these functions.

-

Parts need:

-

Fully defined sketches.

-

Symmetry in construction if

the model is also symmetric about a plane or multiple planes or axes

-

To have a round or rectangular

hole(s) or slot(s) or an extruded boss(es) for use as a reference for the

insertion of additional parts

-

Hole Wizard holes in the base

for mounting to some external structure.

-

The assembly needs:

-

Fully defined except for the

parts that need to move

-

At least 3 different Items from

the Toolbox inserted in multiple locations

-

Insert a Limit or Screw Mate

or an Advance or Mechanical Mate of your choosing.

-

Explode View configuration

-

Exploded Line Sketch for all

components

Instructional Videos:

|

- |

|

|

|

|

-

| Week

6:

Design

Assignments due:

On the

first day of class this week come to class with the completed assignments

from Week 5 in preparation for your In Class Evaluation (ICE). See

details below.

Check

the section on "Out of Class Design Assignment Details" below. including

information on your Final Project Abstract and categories.

Deadlines:

Friday:

Week 6 ICE redos, Your Assembly Model Assembly per the ICE

checklist. There will no redos for this so make certain that you

have it correct in class on Thursday. |

In

Class exercises and assignment details:

In Class Evaluation

(ICE) (3 items). Similar to previous weeks: Click here for your Week

6 ICE Grading Criteria and the Gas

Regulator Drawing, print these out, fill in the needed information

including your name, follow the instructions and hand both of these documents

in at the instructor's desk at the end of the evaluation. On the

first day of class this week we will have an evaluation of the models completed

up to Week 5. Review all of the videos that have been posted and

listed on this site to ensure that you have the following items covered

properly for Week 6's evaluation. The evaluation criteria may include:

-

New Part (20pts) more information

soon

-

Completeness with symmetry notice

the location of the Origin.

-

Correct starting plane, front

-

Material Aluminum

-

Fully defined sketches with

dimensions

-

Correct features

-

More information soon

-

New Assembly (using some modeled

parts from previous weeks) (20pts)

-

Complete with all of the parts

(3pts)

-

Take the unsymmetrical parts

and make them symmetrical (3pts)

-

Rename the Part (1pt)

-

Part fixed to the origin and

on top of the Feature Manager Tree (2pts)

-

Modify the Part so that the

Hole Wizard Holes match the options in the other Part (2pts)

-

Install or redefine the mates

for the Part (2pts)

-

Length of the fastener.

Enter that Length here ________________ (2pts)

-

Properly mated and everything

fully defined including fasteners (5pts)

-

Extras and errors

-

Assembly Model (30pts)

Criteria as defined in the

Week 5 section above

-

Out

of Class Design Assignment details:

-

ED Book

-

Final Project Abstract

-

Click here for a grading guide

on your Final

Project Abstract

-

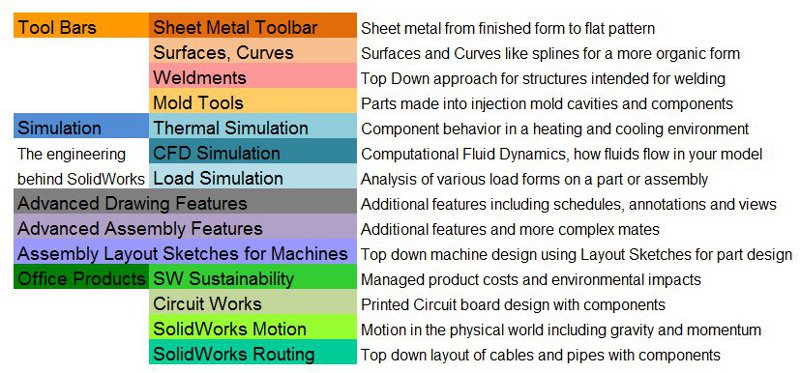

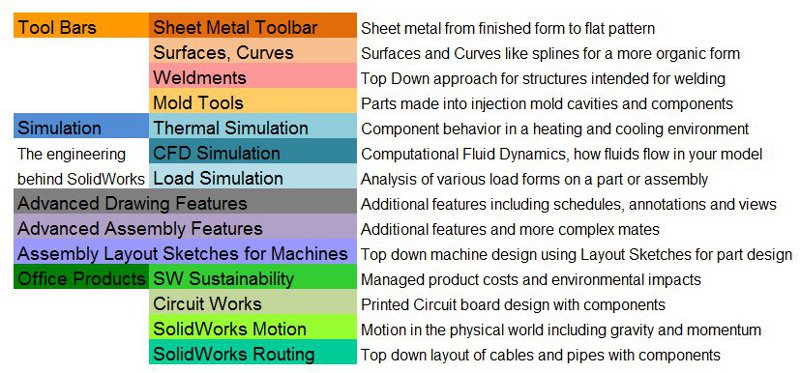

Choose a toolbar or function

to study practice and then demonstrate during your Final Project

presentation from the categories or subcategories listed below, if you

want to choose something different from what is listed please see me.

-

Drawing Template File information

Back

Up:

Follow the book with the

following exclusions, inclusions and modifications as listed below.

-

Create the Millimeter file first,

save it, then resave it as your inches file making the appropriate changes

for the units. Start from the beginning of the project and follow

all of the steps listed.

-

Page 3-9, the bottom of the

page, when it discusses the units make certain that you also assign inches

as the "Dual Dimension Length" with 3 units after the decimal (like we

have been doing all quarter)

-

Save your file to "DRAW-MM-ANSI"

in your template folder.

-

Page 3-10, top of the page,

make certain your font and text size are as described (the default annotation

size is set at about 1/8" which is appropriate for large text, notes and

smaller text will be about 3/32", we will use this when needed in class)

-

Page 3-10, middle of the page,

change the bent leader to a length of 2mm as opposed to the default value.

You will find this location using information in the image below.

-

Page 3-11, top of the page,

Create the following layers and setting as listed below:

-

name: Titeblock-Border, color:

Dark Blue

-

name: Dimensions, color: Red

-

name: Sheet Notes, color: Green

-

name: Hidden Dims, color: Blue

(turn off this layer)

-

Page 3-13, middle of the page,

know about "Edit Sheet" and "Edit Sheet Format" for the test.

-

Page 3-14, bottom of the page,

enter your company name not D&M and the font size and style of your

choosing, make certain it fits the space it is located in on the Title

Block.

-

Page 3-15, bottom of the page,

insert the drafting standard notation ANSI Y14.5 in addition to and after

the text that is provided

-

Page 3-16, top of the page,

make certain that you change the millimeter values to inch equivalents

when you make your inch template file, you will be graded on this!

-

Page 3-17, top of the page,

create a logo using the following guidelines in a style of your choosing.

-

Include a company name, address,

phone number and website address below, nearby or included in your logo.

-

Choose a name and style that

fits your career ambitions or personality. You may design something

in SolidWorks, AutoCAD, Paint, Photoshop, Word or another design program.

Use the following criteria:

-

Your logo must be unique, no

credit for someone else's work

-

An image

-

Inserted to the left or in between

the Proprietary and Confidential box in the titleblock

-

Draw sketch lines around it

(on the Titeblock-Border layer) and make the logo fit the space and look

neat

-

Does not have to look 3D or

in color (they usually are not in color on engineering drawings)

-

Include some graphical styling

including various line sizes, fonts, hatching and other techniques

-

extra credit for extra design

styling

-

Below is my logo and would represent

a design that meets the criteria described above.

-

Below are some additional logos

from various engineering and architectural drawings that I have found over

the years. These were designed in AutoCAD.

-

Save your file then resave it

as your inch template, change all of the annotations and settings to inches

then save your file.

-

Assembly Model Parts and Assembly

Drawing information

Back

Up:

Drawing assignments.

Once you have completed your drawing template files you can use them for

your Assembly Model parts and assembly drawings Design Assignments (explained

below) due this week.

-

Insert the "Guide" and "Guide

Rod Assembly" for an Exploded View, as described in the rest of Project

3. Concurrent with the "Guide" and "Guide Rod Assembly" insert your

more detailed part from your Assembly Model and your Assembly Model assembly

design from last week into two similar drawings using the same parameters

as described in the book.

Instructional Videos:

|

- |

|

|

|

|

-

| Week

7:

Design

Assignments due:

Exam

this week, check back for details.

Deadlines:

Monday:

ICE, drawing files from Week 6 as part of your weekly ICE and the Mystery

Part. We will discuss your Final Project ideas.

Tuesday:

First Examination, Final Project abstract due

Thursday:

Hand back drawings from Monday's ICE for redos.

Friday,

5pm: Redos on your drawing files. |

In

Class exercises and assignment details:

In Class Evaluation

(ICE) (2 items). Similar to previous weeks: Click here for your Week

7 ICE Grading Criteria and the Wagon

Handle Mount drawing print these out, fill in the needed information

including your name, follow the instructions and hand these in at the instructor's

desk at the end of the evaluation. On the first day of class this

week we will have an evaluation of the drawings that you completed in Week

6. Review all of the videos that have been posted and listed on this

site to ensure that you have the following items covered properly for Week

7's evaluation. The evaluation criteria will include:

-

Assembly Model Part Drawing,

print before class, points off for printing during class and even more

after class (15pts)

-

Front, Top, Right, Views (3pts)

-

Section View (1pt) Auxiliary

View (1pt), Detail View (1pt)

-

Appropriate annotations for

the sections, details and auxiliary views (1pt)

-

Views laid out with equal spacing

between left right and top and bottom (1pt)

-

Appropriate dimensions (3pts)

neat and orderly (2pts) Dimension layer (1pt)

-

View labels for each view (1pt)

on Sheet Notes layer (1pt)

-

Errors and Extras

-

Assembly Model Assembly

Exploded Drawing, print before class, points off for printing during class

and even more after class (15pts)

-

All Parts (3pts)

-

Exploded view, shaded with edges

(2pts)

-

Explode line sketches (1pt)

-

Explode neat, orderly, easy

to read (1pt)

-

Bill of materials with Item

Number, Description, Material, Part Number and Qty columns filled in (3pts)

-

BOM neat and orderly (1pt)

-

Balloons (1pt) with circular

split line for Item Number and Qty (2pts)

-

Balloons neat and orderly (1pt)

-

Errors and Extras

-

Title Block Items (10pts)

-

All items apparent (1pt)

-

Company name filled in and in

border (1pt)

-

File name fits (1pt)

-

Unless Otherwise Specified section

filled in properly (1pt)

-

Interpret Geometric Tolerancing

section filled in properly (1pt)

-

Logo, effort, unique, (2pts)

fills the box, company name, address, phone number, web address (2pts)

-

Proprietary section filled in

(1pt)

-

Mystery Part to be used for

the exam on Tuesday, no redos on this part (20pts)

-

Completeness with symmetry,

notice the location of the Origin. (4pts)

-

Material AISI 1020 (1pt)

-

Correct starting plane, top

(1pt)

-

Fully defined sketches with

dimensions (2pts)

-

Various features (6pts)

-

Rename your features (not Hole

Wizards or fillets) (2pts)

-

Find the Mass _________, precision

at 3 units after the decimal (4pts)

-

Find the Center of Mass at 3

units after the decimal, x________, y________, z________ (3pts)

-

Extras and errors

Examination

details:

You

will have your first examination on Tuesday of this week in 2 parts.

The written portion will be per the syllabus and the design assignment

portion will be as described below:

-

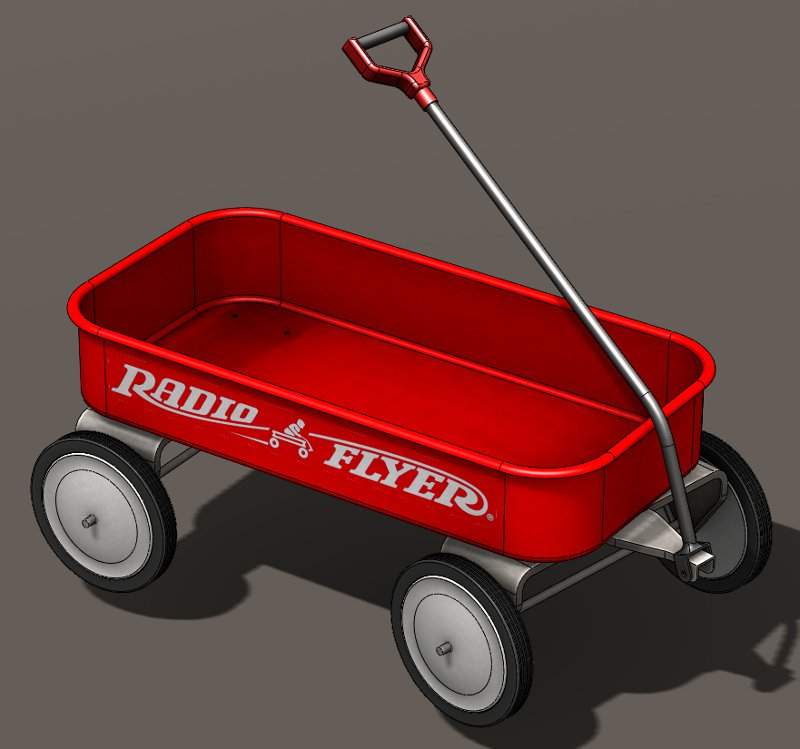

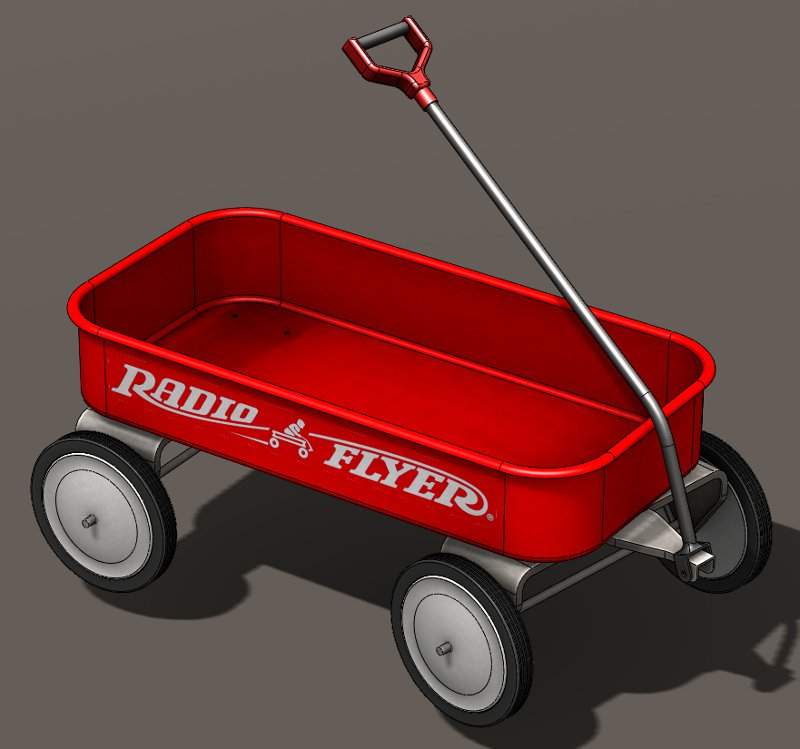

Model the little red wagon below.

-

The Axle, 1/2 inch by

24 inches, "AISI 1020 Steel, Cold Rolled"

-

Download the following file

for your Wagon

Wheel Mount

-

Create a sub-assembly using

the Wagon Wheel Mount (front and back configuration), Wheel Tire

sub-assembly and the Axle to save time during the exam.

-

Download the following file

for your Handle

Bar

-

Model an Axle Hub Cap,

your design, mate symmetrically over the axle without clearances or interferences

and fully defined to the Axle. Extra credit.

-

Wagon Handle Mount Pin,

mate symmetrically without clearances or interferences and fully defined

to the Handle Bar. Extra credit.

Instructional Videos:

|

- |

|

|

|

|

-

| Week

8:

Schedule

for this week:

Threaded

Fastener assignment will be covered in class on Thursday.

The

Spur Gear Design assignment: Follow the videos at the links below.

Tuesday

we will go over the results of the first exam. We will then spend

the rest of the class period demonstrating 3D printers. Additional

details below.

Friday,

hand in your 3 revolved features parts and one image by 5pm. |

In

Class exercises and assignment details:

In Class Evaluation

(none this week because of the holiday)

Out

of Class Design Assignment details:

-

SG Book,

-

Lesson 9, 3 revolved parts,

design 3 revolve features parts per the requirements below, parts and images

due by Friday of Week 8:

-

The first part needs to resemble

a vase or candlestick similar to the image on page 111

-

Two other parts parts using

a revolved feature of your choice (bowls, drinking glasses, wine glasses,

cups, trays, tops, lamps, lighting fixtures, hub caps, lids, fasteners,

etc... anything that can be created using a revolved feature)

-

All part sketches are fully

defined

-

Choose your best part to make

a photo real image, Using PhotoView 360 (see videos below), per the following

requirements. The class will vote on the best image for the Week

9 ICE:

-

Model needs to fill the image

-

Using the PhotoView 360 Options

choose the following:

-

choose "Best" resolution

-

jpg format

-

800 pixels wide, variable height

as needed

-

In the Display Manager tabs

select

-

Appearances, choose an appearance

if you don't have or don't like the material selected on the part

-

Decals only if appropriate,

if chosen do not use the default ones create your own for extra credit

-

Scenes, choose a scene

-

Lights, add custom Spot or Point

light with settings other than default, make certain you turn these on

for PhotoView 360

-

Define a camera position and

use this for your image

-

Extra credit for extra effort

and extra images

-

Lesson 10, models as shown,

Chisel and Screwdriver only

-

ED Book

-

Projects 4 (from Week 7) and

5, skip the part on Mold Tools in Project 4

-

Ex 4.4 Screw and Ex 4.9 Plate,

model as shown. Your Week 8 ICE will involve modifications to either

one of these parts.

-

Ex 5.7, Flange Pipe, information

on this soon and will involve revolve, sweep and lofted (using guide curves)

features.

-

Threaded Fastener Assignment

(evaluated as part of Week 10's ICE)

-

Spur Gear Design Assignment

(evaluated as part of Week 10's ICE)

Instructional Videos:

|

- |

|

|

|

|

-

| Week

9:

Design

Assignments due:

On the

first day of class this week come to class with the completed assignments

from Weeks 7 and 8 in preparation for your In Class Evaluation (ICE).

See details below.

We will

cover Geometric Dimensioning and Tolerancing this week, details soon.

The Yakima

SolidWorks Users Group meeting is on Thursday, this is an extra credit

assignment, let me know if you me to coordinate carpooling. Visit

the website for additional information: YSWUG |

In

Class exercises and assignment details:

In Class Evaluation

(ICE) (3 items and an extra credit item). Similar to previous weeks:

Click here for your Week

9 ICE Grading Criteria and the Iron

Pipe drawing, print these out, fill in the needed information including

your name, follow the instructions and hand these in at the instructor's

desk at the end of the evaluation. On the first day of class this

week we will have an evaluation of the models that you completed in Weeks

7 and 8. Review all of the videos that have been posted and listed

on this site to ensure that you have the following items covered properly

for Week 9's evaluation. The evaluation criteria may include:

-

Vote on the Revolved Features

part image from Week 8 in the Design Gallery below that you

find exceptional. Vote for your first 3 choices by number.

-

Screw part (20 pts),

referring to the image make modifications to your part that you designed

last week.

-

Completeness with symmetry,

notice the new location of the Origin. (4pts)

-

Material, AISI 316 Annealed

Stainless Steel Bar (1pt)

-

Correct starting plane, Front

(2pts)

-

Fully defined sketches with

proper dimensions and sketch relations (2pts)

-

Proper precision on appropriate

dimensions (2pts)

-

Rename your features (2pts)

-

Find the Mass, precision at

4 units after the decimal 0.0053 lb (4pts)

-

Find the Center of Mass at 4

units after the decimal

x 0.0000 in,

y -0.8792 in, z 0.0000 in (3pts)

-

Extras and errors

-

The Plate, (20pts)

-

Completeness with symmetry,

location of the Origin (2pts)

-

Material (1pt)

-

Correct starting plane (1pt)

-

Fully defined sketches with

proper dimensions and sketch relations (2pts)

-

Rename your features (1pt)

-

Find the Mass, precision at

4 units after the decimal 217.7190 g (2pts)

-

Find the Center of Mass at 4

units after the decimal

x 140339 mm, y 7.4020

mm, z 0.0000 mm (3pts)

-

Change A, B and C (3pts)

-

Find the Mass, precision at

4 units after the decimal 699.6520 g (2pts)

-

Find the Center of Mass at 4

units after the decimal

x 17.3962 mm, y 10.1655

mm, z 0.0000 mm (3pts)

-

Extras and errors

-

The Screwdriver, SG (10pts)

-

Completeness with symmetry (1pt),

locate the origin between the handle and the shaft. (1pt)

-

Fully defined sketches with

proper dimensions and sketch relations (2pts)

-

Handle color (1pt)

-

Rename your features (1pt)

-

Proper Loft Feature (2pts)

-

Loft Start/End Constraints,

start Tangency to Face end Normal to Profile (2pts)

-

Extras and errors

Iron Pipe (30pts)

you can get started on this now (if you read this before the ICE on Monday

as you should). Check out the last video in the Week 8 section above

titled: 149.

Creating a Lofted Boss/Base on a Simple Part, Options, Guide Curves

you'll need to know about Lofts and Guide Curves for this portion of this

evaluation. The pipe is a nominal 6 inch cast iron pipe (look up

the OD and ID dimensions). Pipe is 24 inches long including the flange.

I would suggest modeling in the order shown

-

Completeness with symmetry,

location of the Origin (4pts)

-

Material, Ductile Iron (2pts)

-

Correct starting plane, Right

(2pts)

-

Use a value for the Outside

Diameter of a 6 inch cast iron pipe from the Mueller Co (2pts)

-

Loft Feature for the taper on

the flange per the drawing using guide curves (2pts)

-

Hole Wizard Hole, 13/16”, Through

All, on a 11.925” hole circle (2pts) circular pattern (2pts)

-

Cut the Inside Diameter using

data from the Mueller Co (2pts)

-

Sweep Cut using the profile

shown for a pipe gasket (3pts)

-

Find the Mass, precision at

4 units after the decimal 90.6067 lb (3pts)

-

Find the Center of Mass at 4

units after the decimal

x 6.8736 in, y 0.0000

in, z 0.0000 in (6pts)

-

Extras and errors

-

The Mystery Extra Credit Part,

(10pts), chosen from either Project 4 or 5

-

Completeness with symmetry (4pts),

location of the Origin (1pt)

-

Material (1pt)

-

Correct starting plane (1pt)

-

Fully defined sketches with

proper dimensions and sketch relations (3pts)

Out of

Class Design Assignment details:

GD&T drawing

-

Create a drawing of one of your

parts for your Final Project using Geometric Dimensioning and Tolerancing

items learned from this week. See the ICE section in Week 10 for

additional information.

Instructional Videos:

|

- |

|

|

|

|

-

| Week

10:

Design

Assignments due:

I will

extend the deadline for redos from Week 9 to Thursday at 5pm of Week 10.

Mass and Center of Mass values can be found in the Week 9 section above.

On the

first day of class this week come to class with the completed assignments

from Weeks 8 and 9 in preparation for your In Class Evaluation (ICE).

See details below.

Schedule:

Monday:

ICE completed before class, work on Final Projects for the balance of the

class period.

Tuesday:

Final Project Pre-Presentations, plan on spending about 2 minutes presenting

your project to the class. Work on Final Projects for the balance

of the class period.

Thursday:

Redos from Week 9 due by 2pm, markups in the Box.

Exam

2, the CSWA exam. Arrive between 2pm and 3pm. No late arrivals without

penalty. Once you start the exam you have 3 hours to complete it,

details below.

Friday:

Redos from Week 10 due by 5pm, markups in the Box. |

In

Class exercises and assignment details:

In Class Evaluation (ICE)

(4 items). Similar to previous weeks: Click here for your Week

10 ICE Grading Criteria, print this out, fill in the needed information

including your name, follow the instructions and hand these in at the instructor's

desk at the beginning of class. On the first day of class this week

we will have an evaluation of the assignments that you completed in Weeks

8 and 9. Review all of the videos that have been posted and listed

on this site to ensure that you have the following items covered properly

for Week 10's evaluation. The evaluation criteria will include:

-

Threaded Fastener Project

(20 pts) refer to the Grading Criteria for additional information, available

at the link above.

-

Spur Gear Design Assignment

(40

pts) refer to the Grading Criteria for additional information, available

at the link above.

-

The Iron Pipe GD&T

Drawing ED 5.7 (30 pts) Using the description below add the various Geometric

Dimensioning and Tolerancing text and symbols to a new drawing of your

Iron Pipe assignment from Week 9. Refer to the Grading Criteria for

additional information, available at the link above.

-

Final Project Part GD&T

Drawing (30 pts) From your Final Project chose a part of your choice and

create a new drawing. Refer to the Grading Criteria for additional

information, available at the link above.

-

The New Part and

GD&T Drawing, to be announced (30pts) We will work on

your Final Projects on Monday instead of a modeling assignment during the

In Class Evaluation. The assignments as listed above will be due

at the beginning of the class period.

-

Exam 2, the CSWA exam.

The following 5 items need to be covered for you to take and get credit

for this exam:

-

Click on the following link

to download your: Tangix

VirtualTester Program. Download and install this program on your

classroom computer on the day of your exam, Thursday.

-

Click on the following link

to get a list of your VirtualTester

Voucher Codes referencing the last 4 digits of your student ID number.

-

Click on the following link

to create a VirtualTester

account, using your email address, so you can receive and publish your

certificate (a requirement for taking and getting credit for this exam).

-

Click on the following link

for a video demonstration on how to get published (a requirement for getting

credit for this exam):

-

Send me your certificate in

pdf format so I can post it on the website (a requirement for getting credit

for this exam).

Out of

Class Design Assignment details:

Work on your Final

Projects

Instructional Videos:

Information soon

|

- |

|

|

|

|

-

| Final

Project and presentations, Wednesday, March 13, 2pm to 4pm in

the CAD Lab.

Visit

the links in this section for information on your Final Project. |

Click

on the following links referencing you Final Project:

Presentation

Guidelines: Click on the following link for a document

providing a suggested guideline for your Final Project Presentation. Final

Project Presentation Guidelines

Peer

Evaluation: Click on the following link for a copy

of the presentation Peer Evaluation. Final

Project Peer Evaluation

Evaluation

check list: Use this as a guide for preparing for

your Final Project and presentation: Final

Project Grading Criteria

Sample

Drawing Images: View the images below and use them

as a guide to layout your own sheet set.

-

-

Some

images of your Final Project Presentations

Back

|