|

|

|

|

|

|

-

| Week

1:

Announcements:

Come

to the first class of Week 2 prepared by modeling the Class Design Projects

listed in this section below.

Link

to Wednesday's Power Point Presentation named

A

Short History of CAD, Computer Aided Design.

Books,

Two total maybe, you will also learn about SolidWorks through video tutorials.

The

Ultimate GD&T Pocket Guide

Available

at the bookstore

|

Engineering

Design Using SolidWorks (maybe)

Available

on

Amazon

|

d

Getting

Started:

Download

your SolidWorks software, the SolidWorks Student Edition, check the links

and procedures on the Student

Resources web page. Every student enrolled in a SolidWorks course

can download a student version of the software for thier own personal use,

with limitations of course.

And as

a backup, and for your convenience, the CAD

Lab is available everyday except for Saturdays.

This

week's videos can be found on the Instructional

Video Page in the Week 1 section. Week 1 means that you need

to view, practice and understand these videos before the start of Week2.

Below

is a section describing your Class Design Project for this week.

By the beginning of Week 2 have the Week 1 Class Design Project completed

and ready to send in.

Think

about your Final

Design Project, it will serve as your final evaluation for the quarter.

And its a design of your choosing (within reason). Submit a Final

Design Project Proposal at the beginning of class on Wednesdy of Week 2.

Click on the above link for more information.

There

will be a Weekly Design Evaluation (WDE) on Wednesday of Week 2 based on

Week 1's Instructional Video content and the Class Design Projects listed

below.

|

In

Class Demonstrations:

Week 1

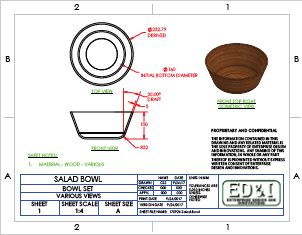

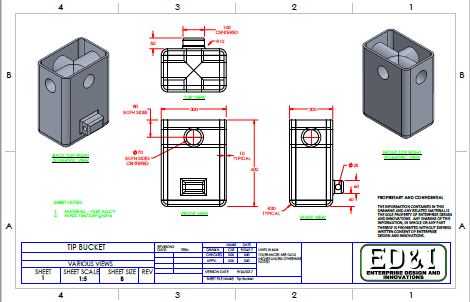

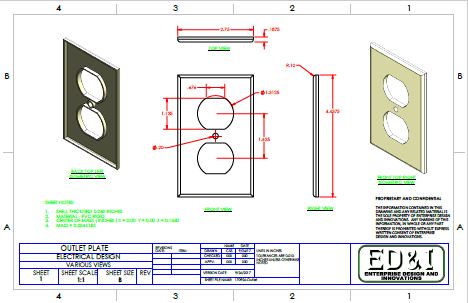

- Class Design Projects (click on the linked images below):

-

Salad Bowl

-

Tip Bucket

-

Outlet Plate

Week

1 Instructional Videos, click here

-

-

| Week

2:

On Friday

I will return your graded WDEs. We will also go over the gradesheet

and the Oulet Plate model as a step by step exercise.

By the

end of Week 2, you will have viewed and practiced the Instructional Videos

available so far and have the Week 2 Class Design Projects completed and

ready for evaluation.

A new

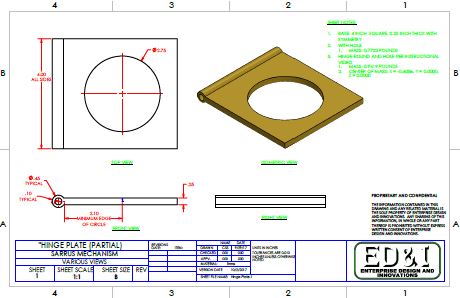

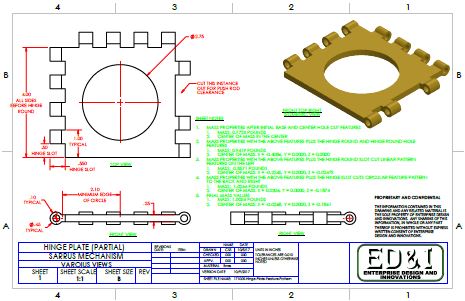

Hinge Plate drawing has been uploaded have this model ready by your WDE

on Wednesday of Week 3.

|

-

Weekly

Design Evaluation (WDE) details (Wednesday - 4 items):

-

Terminology Comprehension Section

(TCS) (short answer, multiple choice, True False questions) (20pts)

-

Class Design Section (CDS) (20pts)

-

Part 1 (10pts) one of the parts

from last week's Class Design Projects

-

Material, Completeness with

symmetry (1pts)

-

Orientation (1pt)

-

Fully defined sketches with

dimensions (2pts)

-

Extrude, Feature Fillet, Shell,

Extrude Cut for holes (1pt each)

-

Mass and Center of Mass (Hint,

Extrude blind for direction to toward the front, not the Mid Plane) (2pts)

-

Extras and errors

-

Part 2 (10pts) new part to be

modeled in class

-

Units millimeters, Material

(1pt)

-

Completeness with symmetry,

origin on the Front Plane (direction toward the back), Right and Top Planes

in the center (2pts)

-

Fully defined sketches with

dimensions (2pts)

-

Rename your Extrude Boss/Base

Features to “Base 1” and “Base 2” Cut Extrudes to “Side Holes” and “Vertical

Holes” (Hint, cut these holes from the Right and Top Planes, Through All

Both) (1pt)

-

Extrudes (4), Feature Fillet,

Shell, Extrude Cut for holes (4) (2pts)

-

Mass and Center of Mass (see

drawing) (2pts)

-

Extras and errors

-

Final Design Section (FDS) (10pts)

-

Final Design Project Proposal,

due at the beginning of class on Wednesday - or before class via email.

Week 2

- Class Design Projects (click on the linked images below): more

information will follow soon including new videos.

Topics

this week include:

-

Fake (alternative)

Template Files,

-

Different

Sketch Tools including the 3 point arc, tangent arc, centerpoint arc, center

of circle on line (tangent) collinear sketch relation, angle lines and

dimensions. Command Manager customize option,

-

Features:

Hole Wizard.

-

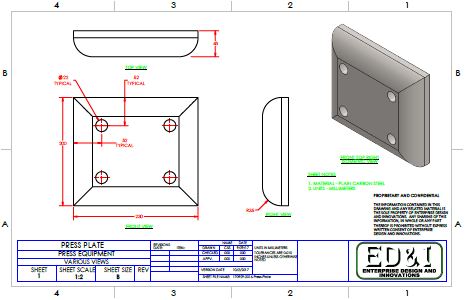

Press Plate

-

-

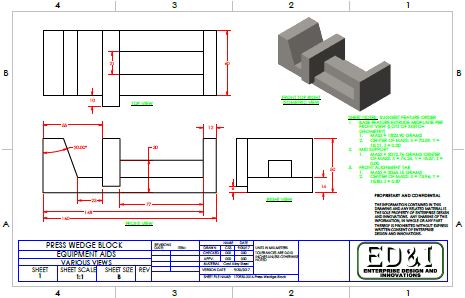

Press Wedge Block

-

-

Schmet's Hook

-

-

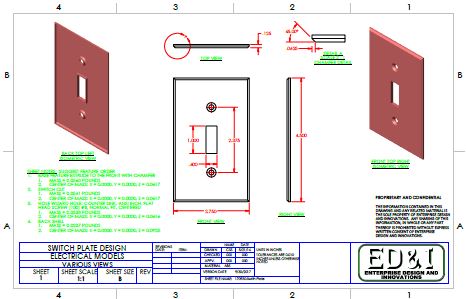

Switch Plate

-

-

In Class - Hinge Plate

-

Week

2 Instructional Videos, click here

-

-

| Week

3:

On Friday

we will review our second WDE.

Most

of the class did not do well on the Schmet's Hook project, so we will go

over that again in class on Friday. Also, as a class exercise, I

will examine and fix every student file on the hook so I can show you how

to use best practices to get the correct mass properties. This will

provide you the opportunity to hand in a corrected model for re-evaluation

by Monday's deadline.

|

-

Weekly

Design Evaluation (WDE) details (Wednesday - 4 items):

-

Terminology Comprehension Section

(TCS) (short answer, multiple choice, True False questions) (20pts)

-

Class Design Section (CDS) (10pts)

-

Part 1 (10pts) one of the parts

from Week 2's Class Design Projects

-

Units, Material (1pt)

-

Origin at bottom, Front Plane

Extrude forward (1pt)

-

Fully defined sketches with

dimensions (1pt)

-

Features (1pt)

-

Hole Wizard (2pts)

-

Mass and Center of Mass (4pts)

-

Extras and errors

-

Part 2 Clip Roller (20pts) new

part to be modeled in class

-

Units inches, 4 numerals after

decimal (1pt), Material (1pt)

-

Origin at the center of the

circle, Right Plane (Mid Pane Extrusion) (1pt)

-

Fully defined sketches with

dimensions (2pts)

Features: Extrudes (3pts),

Mirror (1pt), Feature Fillet (1pt), Chamfers (2pts) Hole Wizard (2pts)

-

Rename your features, see image

to the right for suggested feature order (2pts)

-

Mass Center of Mass (see drawing)

(4pts)

-

Extras and errors

-

Final Design Section (FDS) (10pts),

Final Design Project (FDP) start your first part.

-

Material (2pts)

-

Orientation, Symmetry (1pt)

-

Fully defined sketches with

dimensions (2pts)

-

At least 4 Features or a complicated

sketch (4pts)

-

Rename your Features (1pt)

Week 3

- Class Design Projects (click on the linked images below):

-

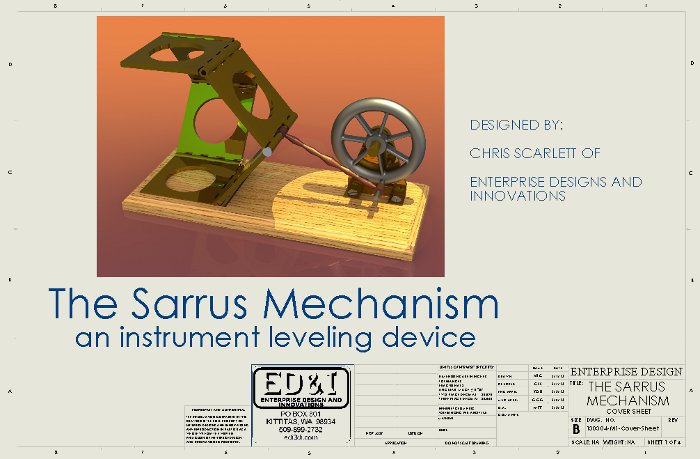

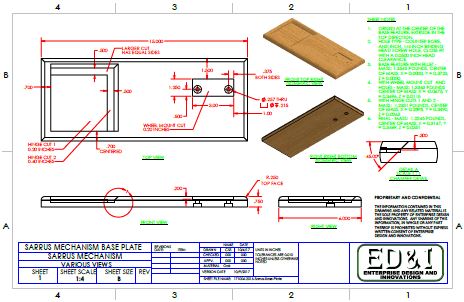

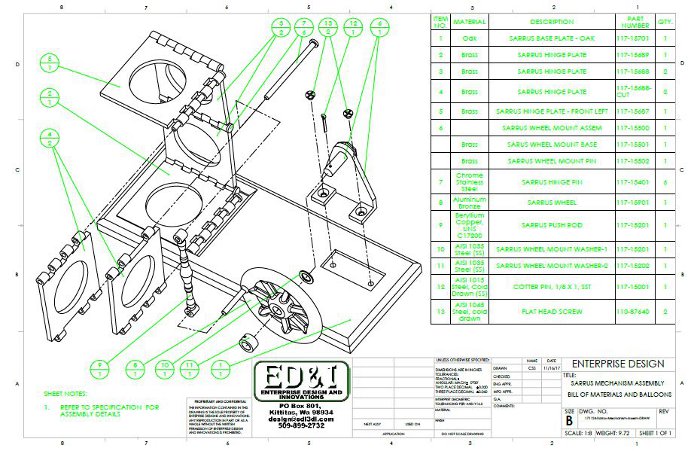

Sarrus Base Plate

-

-

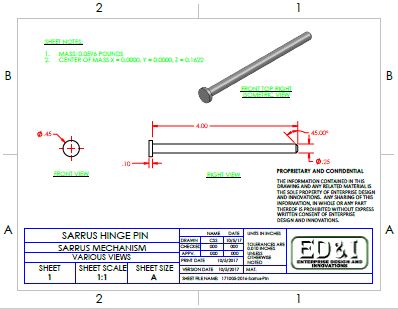

Sarrus Pin

-

-

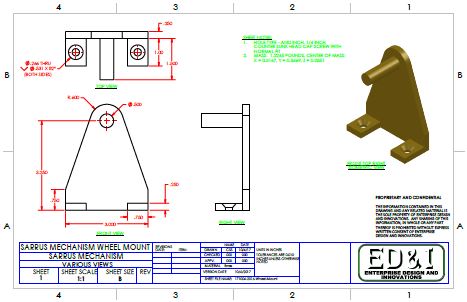

Sarrus Wheel Mount

-

-

Sarrus Hinge Plate

-

Week

3 Instructional Videos, click here

-

-

| Week

4:

For next

week's WDE - practice with the Instructional Videos from Week 4 at the

link below. There are various videos on the revolved, loft and sweep

features. After the videos you will have that specific part completed

for the week.

Continue

to progress on your FDP. You should have either last week's 3 parts

with now an average of 7 features each, or 4 parts with an average of 5

features each or 5 parts with an average of 4 features each. These

will be evaluated during Week 5's WDE.

|

-

Weekly

Design Evaluation (WDE) details (Wednesday - 4 items):

-

Terminology Comprehension Section

(TCS) (short answer, multiple choice, True False questions) (20pts)

-

Class Design Section (CDS) (20pts)

-

Part 1 (10pts) one of the parts

from Week 3's Class Design Projects

-

Modify the elements of the part

(1pt)

-

Units inches, 4 numerals after

decimal, Material (1pt)

-

Origin location, Correct plane

(extrude mid plane) (1pt)

-

Fully defined sketches with

dimensions (1pt)

-

Modify length and width (1pt)

modify Linear Pattern (1pt)

-

Suppress feature - Mass Center

of Mass (4pts)

-

Extras and errors

-

Part 2 - Postion Guide (20pts)

new part to be modeled in class

-

Units millimeters, 2 numerals

after decimal (1pt), Material (1pt)

-

Origin at the center of the

knob, correct plane (extrude up) (1pt)

-

Fully defined sketches with

dimensions, model integrity (3pts)

-

Features: Extrude (1pt), Extrude

Cut (1pt), Linear Feature Pattern (1pt) Extrude Cut (1pt), Hole Wizard

(2pts), Extrude Cut (1pt), Revolved Boss/Base (1pt)

-

Rename your features, see image

to the right for suggested feature order (2pts)

-

Mass, Center of Mass (see drawing)

(4pts)

-

Extras and errors

-

Final Design Section (FDS) (30pts),

Final Design Project (FDP) create 2 more parts (3 total)

-

Material, model completeness,

orientation, symmetry (if needed) (3pts)

-

Fully defined sketches with

dimensions (2pts)

-

At least 4 Features (4pts)

-

Rename your Features (1pt)

-

Errors and Extras

Week 4

- Class Design Projects, click on the linked images below:

-

Sarrus Wheel

-

-

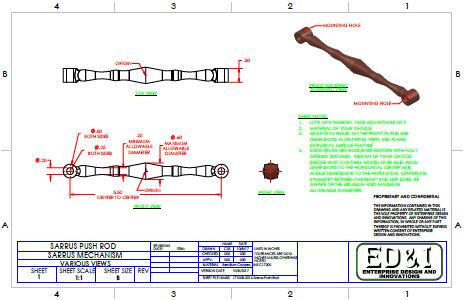

Sarrus Push Rod

-

-

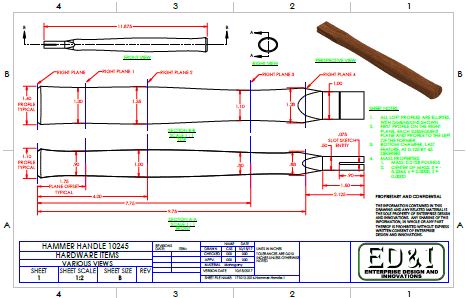

Hammer Handle

-

-

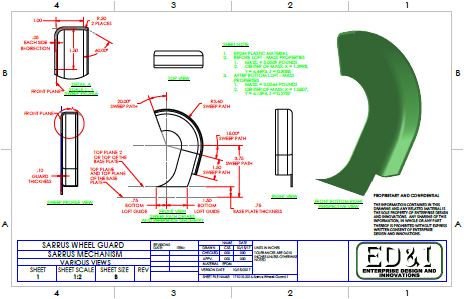

Sarrus Wheel Guard

-

Week

4 Instructional Videos, click here

-

| Week

5:

Videos

and files for this week will concentrate on SolidWorks Assemblies.

Please view the content below. For the Hammer Assembly, click on

the image to download the Hammer Head part that will compliment your Hammer

Handle in making your Hammer assembly.

Continue

to progress on your FDP. We will be looking for your FDP assembly

as a portion of the Week 6 WDE.

|

-

Weekly

Design Evaluation (WDE) details (Wednesday - 4 items):

-

Terminology Comprehension Section

(TCS) (short answer, multiple choice, True False questions) (20pts)

-

Class Design Section (CDS) (20pts)

-

Part 1 (10pts) one of the parts

from Week 3's Class Design Projects

-

Modify the elements of the part

(1pt)

-

Units inches, 4 numerals after

decimal, Material (1pt)

-

Origin location, Correct planes

(1pt)

-

Fully defined sketches with

dimensions, model integrity (1pt)

-

Mass Properties

-

Part 2 - Crucible Bucket (20pts)

new part to be modeled in class

-

Units inches, 2 numerals after

decimal, Material (1pt)

-

Fully defined sketches with

dimensions, model integrity (3pts)

-

Features: Lofted Boss/Base (2pts),

Swept Boss/Base (2pts), Revolved Boss/Base (2pts), Three Planes (3pts),

Split Line (1pt), Mirror (1pt)

-

Rename your features, see image

to the right for suggested feature order (2pts)

-

Mass, Center of Mass (see drawing)

(3pts)

-

Extras and errors

-

Final Design Section (FDS) (30pts),

Add more parts or add more features to existing parts (each part gets two

points) and each average feature gets one. Multiply these values

together and add them up to receive a total score of 40 points (proportionally

rounded up), the more stuff the more points.

-

Material, model completeness,

orientation, symmetry (if needed) (20% off each)

-

Fully defined sketches with

dimensions (20% off each)

-

Descriptive Part Name, Rename

your Features (10% off each)

-

Errors and Extras

Week 5

- Class Design Projects, This week we are concentrating on Assemblies.

Clicking on the images below will take you to the Week 5 Instructional

Video page where you can follow a step by step apporach to building these

assemblies.

-

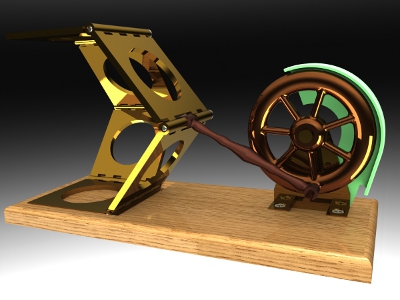

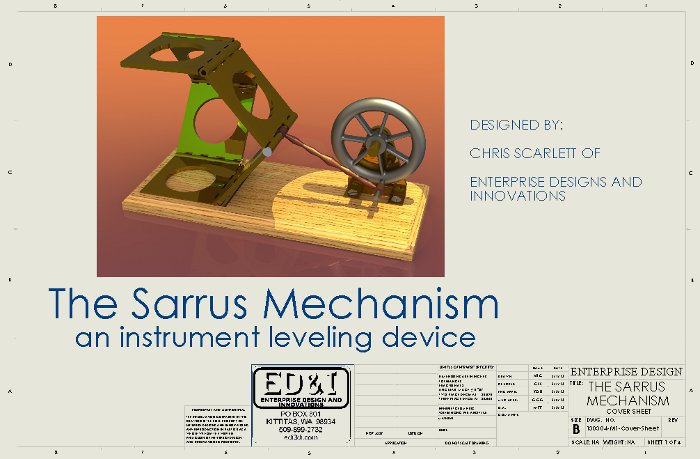

The Sarrus Mechanism Assembly

-

-

The Sarrus Hinge Plate

with Configurations

Week

5 Instructional Videos, click here

-

-

| Week

6:

For this

week's WDE, check the information below.

This

week and next we will focus more on assemblies and your FDP assembly and

parts. Check back for updates.

As a

reminder we will not have class on Friday of Week 6, but continue to progress

on your FDP. Contact me if you need help.

|

-

Weekly

Design Evaluation (WDE) details (Wednesday - 4 items):

-

Terminology Comprehension Section

(TCS) (short answer, multiple choice, True False questions) (20pts)

-

Class Design Section (CDS) 40

points total

-

Out of Class Project – The Sarrus

Assembly (20pts)

-

Standard ANSI Inch, 3 units

after the decimal (3pts)

-

Base Plate fixed to the Origin

(2pts), planes coordinated (2pts)

-

Wheel Mount Fully Defined and

mated in Slot (1pt)

-

First Hinge Plate Fully Defined

and mated in Slot (1pt)

-

Hinge Plate Form (Configurations)

(2pts)

-

Remaining Hinge Plates, five,

with flexibility (1pt)

-

Pins defined, six, mated in

Hinge Holes (2pts)

-

Wheel defined with rotation

(1pt)

-

Wheel Guard Fully Defined (1pt)

-

Toolbox Machine Screws, two,

Fully Defined (2pts)

-

Appropriate Motion (2pts)

-

Extras and errors

-

In Class Project – The Hammer

Hanger Assembly (see instructions) (20pts)

-

Hammer Hanger Plate:

-

Standard ANSI Inch, 3 units

after decimal (1pt), AISI 316 Stainless Steel Sheet (1pt), Rename your

features (1pt), Model complete, Mass Properties (2pts)

-

Hammer Hanger Hook:

-

Standard ANSI Inch, 3 units

after decimal (1pt), AISI 316 Annealed Stainless Steel Bar (1pt), Rename

your Sketches, Planes and Features (2pts), Model complete, Mass Properties

(2pts)

-

Hammer Hanger Assembly:

-

Hammer Hanger Plate Fixed to

the Origin (2pts)

-

Hammer Hanger Hook, Coincident

Mate - Right Plane to the Right Plane of the Assembly (1pt), Concentric

Mate - circular surface to circular surface of the Hanger Plate (1pt),

Parallel Mate – Front Plane to the Front Plane of the Assembly (1pt).

-

Insert Hammer Sub-Assembly (look

for Assembly files) (1pt), Rotate sub assembly approaching proper orientation

(1pt)

-

Hammer Coincident Mate – Front

Plane to Right Plane of Assembly or Hook, (1pt), Distance Mate between

top of handle and Top Plane of Hook of 1.1 inches (1pt), Distance Mate

between the Top Plane of the Hammer and the Front Plane of the Hook of

1.0 inches (1pt).

-

Before you send the file, unsupress

the Parallel Mate (2pts) - the hammer and hook should swing.(2pts)

-

Extra credit for a Limit Mate

on this mate

-

Weekly Design Evaluation - Week

6 - Final Design Section - 20 Points

-

Appropriate part fixed to the

Origin (5pts)

-

Planes coordinated (5pts)

-

Appropriate Mates (6pts)

-

Provide some sort of motion

(4pts)

-

Hole Wizard Holes and Toolbox

Fasteners (extra credit this week, required next time)

-

Material, model completeness,

orientation, symmetry (if needed) (20% off each)

-

Fully defined sketches with

dimensions (20% off each)

-

Descriptive Part Names, Rename

your Features (10% off each) Errors and Extras

Week

6 Instructional Videos, click here

-

-

| Week

7:

On Friday

we will take your homework from Wednesday, and with the various values

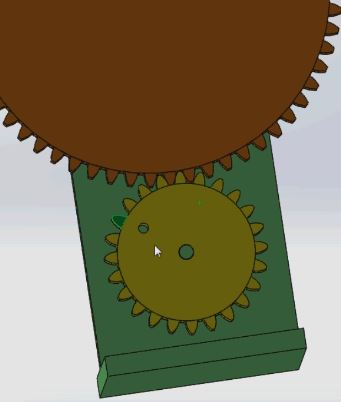

derived, we will design your Spur Gear pairs as a portion of your Spur

Gear Design project. Review information on the Student

Resources Page for the Spur Gear Design. A video with details

is also available in the Week

7 Instructional Video page. This project will count toward your

Week 8 WDE.

MTerminolgy

on Spur Gear Design will be a part of the TCS of the WDE in Week 8.

More

information coming soon.

|

-

Weekly

Design Evaluation, none this week.

Week

7 - Class Design Projects, This week we are working on your FDP Parts and

Assemblies and the Spur Gear design project.

-

Spur Gear Design Project formulas,

as described on Wednesday, solve these before class on Friday, click on

the image below for a printout. Go to the Week 7 Instructional Video

page for additional information.

Week

7 Instructional Videos, click here

-

-

| Week

8:

This

week's WDE will be on Monday, in short you will need the following:

-

Spur Gear

Assembly (completed in class on Friday)

-

Modifications

to the Spur Gears (in class on Monday)

-

FDP progress,

check your score on the Grade Sheet (send before class on Monday)

-

A Rib and

Design Table on one of your FDP parts (send before class on Monday)

For the

TCS, know about the 5 Display Styles, at least 6 Mate types, and be able

to describe the "6 Degrees of Freedom" in an assembly.

For details,

check the information below. |

-

Weekly

Design Evaluation (WDE) details for Monday 11/6/17 - 4 items:

-

Terminology Comprehension Section

(TCS) (short answer, multiple choice, True False questions) emphasis on

Assemblies and gear terminology (20pts)

-

Class Design Section (CDS) 60

points total

-

Out of Class Project – The Spur

Gear Design Project (40pts)

-

Standard ANSI Inch, 4 units

after decimal (1pt), Material of your choice (1pt), Rename your features

(1pt), Model complete (3pts)

-

Properly derived Do, Dp, Dr,

(2pts each gear)

I

-

Dpp, Db (2pts each gear)

I

-

Ta (2pts each gear)

I

-

Tooth Root Perpendicular (2pts

each gear)

I

-

Xc (2pts)

-

Movement with Physical Dynamics

(10pts)

-

Gear Mate, works correctly (6pts)

-

Extras and Errors

-

In Class Project – Gear Modifications

(20pts)

-

Take a screenshot of a spur

gear design and emulate it...

-

Weekly Design Evaluation - Final

Design Section - 30 points total

-

FDP Project - (30pts)

-

Total score, per the Grade Sheet

"WDE FDS" tab, of 30 points. See the video linked on the Week 7 Instructional

Video page for how this is graded.

-

Material, model completeness,

orientation, symmetry (if needed) (10% off each part)

-

Fully defined sketches with

dimensions (10% off each part)

-

Descriptive Part Names, Rename

your Features (10% off each part)

-

Errors and Extras

-

FDP Part modifications 20 points

total

-

Design Table (10pts)

-

Pick a FDP part and include

a Design Table per the video in the Week 7 Instructional Video Page (1pt)

-

Must have at least 6 Excel generated

configurations with variations on dimensional values (6pts)

-

3 Excel generated derived configurations

to suppress or unsupress a feature (3pts)

-

More configurations for extra

credit (0.5 pts each)

-

Rib Feature (10pts)

-

Pick a FDP part and include

a Rib Feature per the video in the Week 7 Instructional Video Page, must

be properly defined (10pts)

-

Week 8

- Class Design Projects, This week we will be initiating SolidWorks Drawings.

More information coming soon.

-

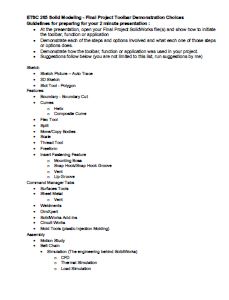

Information on making a selection

for the SolidWorks toolbar, application or function that you wish to demonstrate

to the class as a portion of your FDP presentation during the class final.

(click on the image for more information)

-

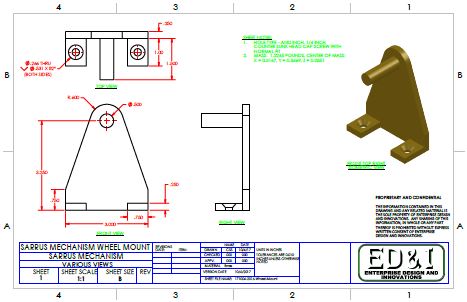

Drawing of the modifed Sarrus

Wheel Mount (coming soon)

Week

8 Instructional Videos, click here

-

-

| Week

9:

This

week's WDE will be on Friday, details in the section below.

This

week we will be focused on SolidWorks Drawings

|

-

Weekly

Design Evaluation (WDE) details for Friday 11/17/17 - 4 items:

-

Terminology Comprehension Section

(TCS) (short answer, multiple choice, True False questions) emphasis on

Drawings and Assemblies (20pts)

-

Class Design Section - 60 points

total

-

Out of Class Project - 10 points

total

-

Drawing Template Title Block

Items (from your printed Sarrus Wheel Mount drawing below

-

Looks complete (1pt)

-

Company name filled in and within

in border (modify text size)(1pt)

-

File name fits (modify text

size)(1pt)

-

Unless Otherwise Specified section

filled in properly (1pt)

-

Interpret Geometric Tolerancing

section filled in properly (1pt)

-

Logo, effort, unique, (2pts)

fills the box, company name, address, phone number, web address (2pts)

-

Proprietary section filled in

(1pt)

-

In Class Project – Sarrus Wheel

Mount Parts, part Modifications, Assembly and Drawing - 60 points total

-

Sarrus Wheel Mount Sub-Assembly

with new parts and modified parts - 20 points total

-

Open your Sarrus Wheel Mount

part and make the following modifications and create some new parts:

-

....

-

New Sarrus Wheel Mount: Material,

Mass Properties

-

Create a new part...

-

Create a sub-assembly...

-

Appropriately defined

-

Send Pack and Go of assembly

-

Sarrus Mechanism Assembly -

Revised - 20 points total

-

Suppress the Wheel Guard

-

Create an inside washer to be

placed between the Sarrus Wheel and the Sarrus Wheel Mount Sub-Assembly

named Sarrus Wheel Mount Washer using existing model geometry

-

Create a new configuration of

this part for the outside washer with a 1/8" cotter pin hole in it.

-

Provide a corresponding hole

on the Sarrus Wheel Mount Pin part designed above

-

Insert the Sarrus Wheel Mount

Assem, in lieu of the Sarrus Wheel Mount part, and fully define this assembly

to the Sarrus Mechanism Assembly

-

Download a 1/8" cotter pin from

3D Content Central from Rhodes Wilkinson

-

Insert the washers and cotter

pin in the appropriate locations, fully defined

-

Make certain that all parts

in the assembly are appropriately defined

-

Sarrus Wheel Mount Drawing -

20 points total

-

Drawing

-

3 standard views (HLR), isometric

view (Shaded), section view of the Front View – positioned to the

right of the Right View (HLV), detail view of the Top View of the Hole

Wizard Hole

-

View Titles labeled, centered,

proper layer

-

Views centered with consistent

offsets,

-

Dimensions, complete, proper

layer, dimension leader offsets

-

Hole Wizard callout on a detail

view

-

Note section with fabrication

details and Mass Properties - Mass and Center of Mass

-

Print this on ANSI B sized paper

-

Weekly Design Evaluation - Week

9 - Final Design Section - 60 points total

-

Name of the toolbar, application

or function that you wish to demonstrate (10pts):

-

FDP Project - (50pts)

-

Total score, per the Grade Sheet

"WDE FDS" tab, of 50 points. See the video linked on the Week 7 Instructional

Video page for how this is graded.

-

Fully defined sketches with

dimensions (not counted if not fully defined)

-

Descriptive Feature names (10%

off each part)

-

Descriptive Part Names, material,

orientation, symmetry (if needed) (10% off each part)

-

Mated not intersecting parts,

parts not fully defined when they should be (10% off each part)

-

Errors and Extras

-

Weeks

9, 10 and 11 - Class Design Projects, This week we will be working more

with SolidWorks Drawings including Explode Configurations, Explode Drawing

Views, BOMs (Bill of Materials) and Balloons.

-

Week

9 Instructional Videos, click here

-

-

| Week

10:

This

week's WDE will be on Monday, the Revolved Features project and contest.

Come to class with a modeled project per the criteria below. We will

work on PhotoView 360 in class on Monday. There will be no TCS or

FDS section on the WDE. Contest winners will get up to 20 points

extra credit.

|

-

Weekly

Design Evaluation (WDE) details for Monday 11/20/17 - 2 items:

-

Class

Design Section - 20 points total, Create a revolved feature part similar

to the wine glass demonstrated in Video 23 on the Week

3 Instructional Video page. It can be any object that can be

produced using a revolved feature such as, but not limited to, a vase,

candle stick holder, coffee cup or mug, jar, bottle, lighting fixture,

drinking glass, dinner plate, etc… look around, find something that can

be modeled - measure it and create it.

-

Revolved

feature part – 20 points total

-

Must contain:

lines arcs and a style spline and multiple features if desired (3pts)

-

At least

30 sketch entities in the primary and one other feature including model

lines, arcs, style splines, reference geometry, and dimensions (6pts)

Extra credit for more.

-

Fully

defined sketches (3pts)

-

Descriptive

part name (2pts)

-

Renamed

features (2pts)

-

Symmetry

(1pt)

-

Material

or Appearance (2pts)

-

Color

(1pt)

-

Errors

and Extras

-

Send part

-

Photo

real image using PhotoView 360 – 20 points total

-

Material

(4pts)

-

Scene

(2pts)

-

Lights

(2pts)

-

Camera

(3pts)

-

Object

fills image (2pts)

-

Object

centered in image (2pts)

-

Good orientation

(1pt)

-

Image

size 800px x 450px or 600px x 1067px (3pts)

-

Errors

and Extras

-

Send image

Weeks

9, 10 and 11 - Class Design Projects, This week we will be working more

with SolidWorks Drawings including Explode Configurations, Explode Drawing

Views, BOMs (Bill of Materials) and Balloons.

-

-

Information on some general

guidlines for your Final Design Project presentation. click on the

image for more information)

-

Week

10 Instructional Videos, click here

-

-

| Week

11:

This

week's WDE will be on Wednesday evaluating a preliminary set of drawings

of your Final Design Project. Plus the usual TCS. Details below.

WDE drawings are due Friday before class, printing during class will result

in a 10% markdown.

Procedures

for printing your Cover Sheet in color will be posted soon.

|

-

Weekly

Design Evaluation (WDE) details for Wednesday 11/29/17 - 4 items:

-

Class

Design Section - 40 points total

-

Generalized

grading criteria for all drawings include:

-

B size

to a pdf file in color (send pdf), then print the pdf in the lab in grey

scale, full size (measure this), (color for Cover Sheet), ANSI dimensioning

standard, units, appropriate precision, appropriate sheet scale, views

laid out with appropriate spacing and symmetry.

-

Title

Block items as described throughout the quarter, all CAPITALs, logo (unique

with company information), part description, file name, company name, units

of measure, dimensioning standard, confidentiality statement (filled in

with your company name), material, drawn by (your initials) and date, checked

by and date, etc…

-

Specific

Grading Criteria:

-

Drawing

Template of your FDP - Title Block Items and Drawing Layout (random part

drawing selected) 10 points total.

-

All CAPITALs

(1pt)

-

Logo -

effort, unique, (1pt) fills the box, company information including: name,

address, phone number, web and email address (1pt)

-

Company

name section (1pt)

-

Part description

section (1pt) file name section (fits) (1pt)

-

Material,

Weight, Units of measure sections (1pt)

-

Drawn

by (initials) and Draw date - today’s date (1pt)

-

Interpret

Geometric Tolerancing section (1pt)

-

Dimensioning

standard, Confidentiality statement section (1pt)

-

Errors

and Extras

-

Cover

Sheet drawing of the assembly of your FDP, graded as follows - 10 points

total

-

Image(s)

of the assembly or an important part of the assembly (will check the assembly

for the items below when grading the final)

-

Material

on parts in the assembly (1pt), Scene (1pts), Lights on (1pt), Camera (1pt)

-

Object

fills image (1pt), Object centered in image (2pts)

-

Aspect

ratio 16:9 (1pt)

-

Errors

and Extras

-

Part drawing

(1) of your choice from your FDP, graded as follows - 10 points total

-

ANSI dimensioning

standard, units, appropriate precision, appropriate sheet scale (1pt)

-

3 standard

views with at least 2 Display Styles (1pt)

-

Isometric

view with Shaded or SWE Display Styles (1pt)

-

2 extra

views – choosing from the Detail View, Projected View, Section View, Crop

View or others, has to add to the information attempting to be demonstrated

with your project (1pt)

-

Dimensions

complete, organized, extension line offsets, Dimension layer 10 minimum

(1pt), 2 different types of tolerances on the appropriate features on your

parts (1pt)

-

At least

3 Datums and 2 unique Feature Control Frames, on the appropriate toleranced

dimensions for the appropriate features or surfaces referring to the datums

(1pt), need to make sense, use your guidebook (1pt)

-

Note section

with fabrication details and Mass Properties (1pt)

-

Views

and annotations laid out with appropriate spacing and symmetry (1pt)

-

View titles

- Sheet Notes layer, CAPITALs, centered below and underlined (1pt)

-

Errors

and Extras

-

Exploded

assembly drawing of your FDP assembly, graded as follows – 10 points total

-

Create

new isometric type view with a different orientation (if needed) to make

it more readable in a drawing (1pt), organized with edge and object offsets,

HLR, proper scale so that it fits but not too crowded (1pt)

-

Bill of

Materials, on the Sheet Notes layer, organized and neat, consistent

row height, rows in logical order, filled in, CAPITALs (1pt), numbers centered,

text left justify (1pt), Columns include – and in order: Item Number, Description,

Material, Part Number and Quantity categories (1pt), get started on this,

does not have to be completely full.

-

Balloons,

circular split line for all parts, item number/quantity (1pt), organized,

easy to read, magnetic line, no overlapping lines, Sheet Notes layer (2pts)

-

Explode

Line Sketches, complete, neat, organized, no stacks, lots of clearance

(2pts) Get started on this, does not have to be complete.

-

Errors

and Extras

At

the end of the evlaution, provide the following items:

Printed

drawings complete after class, I leave at noon.

Send

pdf drawing files after class, before noon

Markup

at the instructor's podium

Weeks

9, 10 and 11 - Class Design Projects, This week we will be working more

with SolidWorks Drawings including Explode Configurations, Explode Drawing

Views, BOMs (Bill of Materials) and Balloons.

-

-

A sample drawing set for your

Week 11 WDE of your FDP. Cover page, assembly page with Exploded

View, Balloons and BOM and a part drawing with dimensioning and GD&T

items. Print per the specifications on the Student

Resources page.

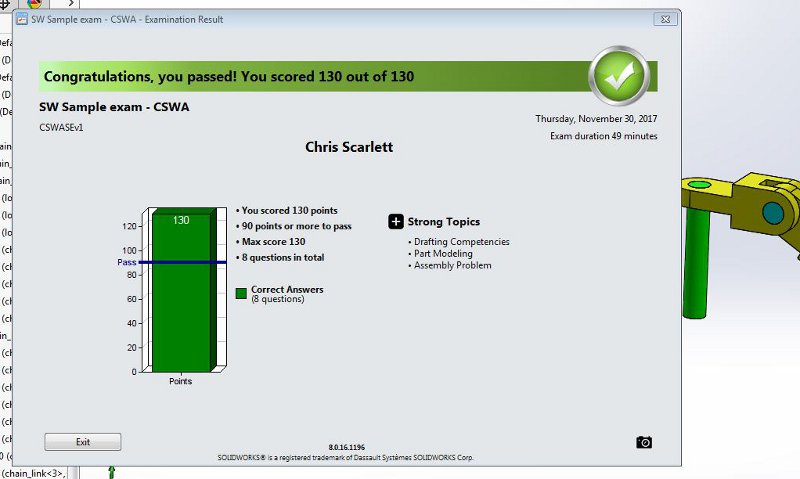

The

CSWA Sample Test - Everyone should be well prepared for this!

-

Week

11 Instructional Videos, click here

-

-

| Finals

Week:

Information

on your Final Design Project - including information on your FDP score,

drawings, presentation and peer evaluation is available below.

|

-

Before

or during the time of the Final Presentation provide the following items:

-

Printed

drawings before the beginning of the presentations

-

Send pdf

drawing files before the beginning of presentations

-

Send FDP

Assembly "Pack and Go" zip file before the beginning of presentations

-

Send FDP

Drawing "Pack and Go" zip files (5 total zip files) before the beginning

of presentations

-

FDP Peer

Evaluation booklet at the end of presentations

|